Introducing Roller Chain Coupling for Pharmaceutical Manufacturing

1. Precision Engineering

Roller chain couplings are precision-engineered to ensure accurate alignment and smooth operation in pharmaceutical manufacturing processes. The high-quality materials used in these couplings provide durability and reliability in demanding environments.

2. Versatile Design

With a versatile design, roller chain couplings can accommodate a wide range of shaft misalignments, making them ideal for various pharmaceutical machinery applications. This flexibility allows for easy installation and maintenance.

3. High Torque Transmission

Roller chain couplings are capable of transmitting high torque loads, making them suitable for heavy-duty pharmaceutical manufacturing equipment. This ensures efficient power transmission and consistent performance.

4. Corrosion Resistance

Manufactured using corrosion-resistant materials, roller chain couplings are ideal for pharmaceutical manufacturing environments where cleanliness and sterility are crucial. This ensures a long service life and minimal maintenance requirements.

5. Cost-Effective Solution

Roller chain couplings offer a cost-effective solution for pharmaceutical manufacturers, providing reliable performance at a competitive price point. Their durability and efficiency make them a valuable investment for pharmaceutical production facilities.

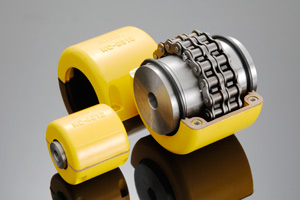

What is a Roller Chain Coupling?

1. Functionality

A roller chain coupling is a mechanical device used to connect two shafts for transmitting power in pharmaceutical manufacturing equipment. It consists of interconnected links wrapped around sprockets to provide torque transmission.

2. Durability

Designed for durability and reliability, roller chain couplings can withstand high torque loads and harsh operating conditions in pharmaceutical production environments. This ensures consistent performance and minimal downtime.

3. Flexibility

Roller chain couplings offer flexibility in accommodating shaft misalignments, angular offsets, and axial movements, making them suitable for a variety of pharmaceutical machinery applications. This versatility simplifies installation and maintenance processes.

4. Maintenance

With minimal maintenance requirements, roller chain couplings are easy to maintain and service in pharmaceutical manufacturing facilities. Regular inspection and lubrication can extend the service life of these couplings.

5. Application

Commonly used in conveyors, mixers, pumps, and other pharmaceutical machinery, roller chain couplings play a critical role in power transmission and equipment operation. Their reliability and efficiency make them a preferred choice in pharmaceutical manufacturing.

What Are the Advantages of Roller Chain Coupling?

1. Efficient Power Transmission

Roller chain couplings provide efficient power transmission, ensuring consistent performance in pharmaceutical manufacturing equipment. This results in smooth operation and increased productivity.

2. Durable Construction

Constructed from high-quality materials, roller chain couplings offer durability and reliability in demanding pharmaceutical production environments. Their robust design ensures long service life and minimal maintenance.

3. Cost-Effective Solution

Roller chain couplings are a cost-effective solution for pharmaceutical manufacturers, offering reliable performance at a competitive price point. This makes them an economical choice for pharmaceutical machinery applications.

4. Versatile Design

With a versatile design, roller chain couplings can accommodate various shaft misalignments and operating conditions in pharmaceutical manufacturing processes. This flexibility simplifies installation and maintenance procedures.

5. Corrosion Resistance

Manufactured using corrosion-resistant materials, roller chain couplings are suitable for pharmaceutical production environments where cleanliness and sterility are essential. This ensures a hygienic and efficient operation.

Key Applications of Hydraulic Couplings

Coming soon…

When to Use Chain Coupling?

Coming soon…

Which Chain Coupling is Recommended for High Torque Loads?

Coming soon…

About HZPT

Basic information: HZPT, established in 2006, is a leading manufacturer and exporter specializing in the design, development, and production of couplings. With a dedicated design and R&D team for 16 years, we offer custom solutions to global customers. Our comprehensive quality inspection system ensures product excellence, with CE and TUV certificates for all products.

Advantages:

- 20 years of ODM and OEM experience

- 100% testing before shipment

- 24-hour customer service

- Best materials and new product designs annually

- Factory direct sales and customization options

Why Choose Us: Our company is renowned for providing top-quality products, excellent customer service, and competitive pricing. With a focus on customer satisfaction and product reliability, we aim to establish successful partnerships worldwide. Choose HZPT for superior coupling solutions in pharmaceutical manufacturing and beyond.