Introducing Roller Chain Coupling for Steel Mills

1. High Durability

Roller chain couplings are known for their high durability, making them ideal for heavy-duty applications in steel mills. They can withstand high torque loads and provide reliable performance in harsh industrial environments.

2. Easy Installation

These couplings are designed for easy installation, reducing downtime during maintenance or replacement. This is crucial in steel mills where efficiency is key to productivity.

3. Flexibility

Roller chain couplings offer flexibility in terms of misalignment compensation, allowing for smooth operation even in situations where shafts are not perfectly aligned. This helps prevent premature wear and tear.

4. Cost-Effective

Being cost-effective solutions, roller chain couplings provide a reliable and efficient way to transmit power in steel mill applications. They offer a good balance between performance and affordability.

5. Low Maintenance

With minimal maintenance requirements, roller chain couplings are a practical choice for steel mills looking to reduce operational costs and increase overall equipment reliability.

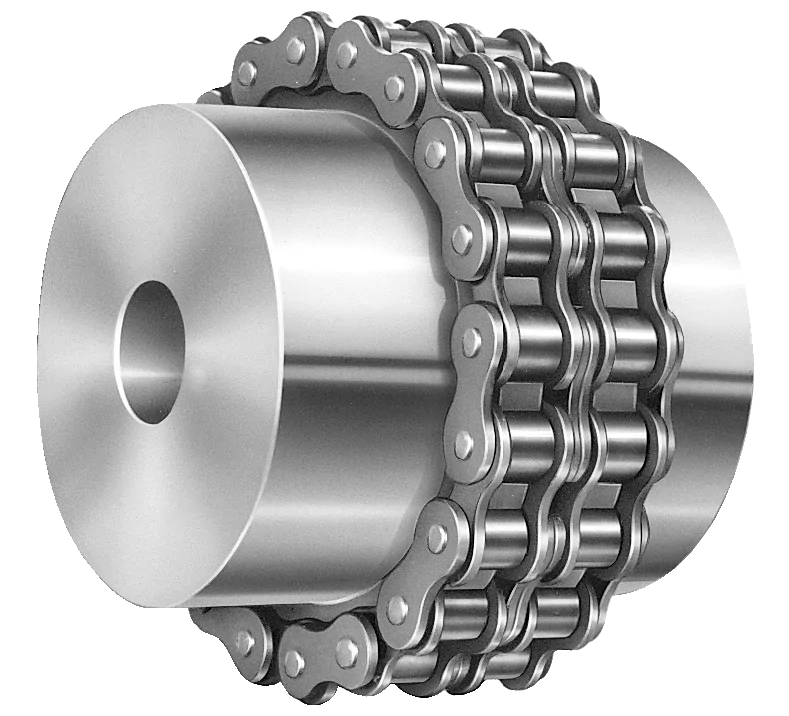

What is a Roller Chain Coupling?

1. Functionality

A roller chain coupling is a type of mechanical coupling used to transmit power between two shafts in heavy-duty industrial applications. It consists of two sprockets connected by a roller chain, providing a flexible and efficient power transmission solution.

2. Design

These couplings are designed to accommodate misalignment and shock loads, ensuring smooth and reliable operation in challenging environments such as steel mills.

3. Benefits

Roller chain couplings offer benefits such as high durability, easy installation, flexibility, cost-effectiveness, and low maintenance requirements, making them a popular choice for industrial applications.

4. Applications

These couplings are commonly used in steel mills, mining equipment, conveyors, and other heavy machinery where reliable power transmission is essential for operational efficiency.

5. Maintenance

Regular inspection and lubrication are recommended to ensure the optimal performance and longevity of roller chain couplings in steel mill applications.

What are the Advantages of Roller Chain Coupling?

1. High Torque Capacity

Roller chain couplings have a high torque capacity, making them suitable for heavy-duty applications in steel mills where power transmission requirements are demanding.

2. Shock Absorption

These couplings can absorb shocks and vibrations, protecting the connected equipment from damage and ensuring smooth operation in steel mill environments.

3. Misalignment Compensation

Roller chain couplings can compensate for angular, parallel, and axial misalignments, reducing stress on shafts and bearings and extending the operational life of equipment.

4. Cost-Effectiveness

Being a cost-effective solution, roller chain couplings offer a good balance between performance and affordability, making them a popular choice for steel mills looking to optimize operational costs.

5. Easy Maintenance

With minimal maintenance requirements, roller chain couplings are easy to maintain, reducing downtime and ensuring the continuous operation of steel mill equipment.

Key Applications of Hydraulic Couplings

1. Steel Industry: Hydraulic couplings are commonly used in steel mills for various applications such as rolling mills, conveyors, and pumps.

2. Mining Equipment: Hydraulic couplings are utilized in mining equipment for power transmission and torque control in heavy-duty operations.

3. Marine Industry: Hydraulic couplings play a crucial role in marine applications for propulsion systems, winches, and deck machinery.

4. Construction Machinery: Hydraulic couplings are essential components in construction machinery such as excavators, cranes, and concrete mixers for efficient power transmission.

5. Agriculture Sector: Hydraulic couplings are used in agricultural machinery such as tractors, harvesters, and irrigation systems for reliable power transmission in demanding environments.

When to Use Chain Coupling?

1. High Torque Applications: Chain couplings are ideal for applications that require high torque transmission and shock load absorption, such as steel mills, mining equipment, and heavy machinery.

2. Misalignment Compensation: Chain couplings are suitable for situations where shafts are not perfectly aligned, providing flexibility and preventing premature wear and tear.

3. Cost-Effective Solution: Chain couplings offer a cost-effective power transmission solution without compromising on performance, making them a practical choice for various industrial applications.

4. Easy Installation and Maintenance: Chain couplings are designed for easy installation and minimal maintenance requirements, reducing downtime and ensuring operational efficiency.

5. Heavy-Duty Operations: Chain couplings are recommended for heavy-duty operations where reliability, durability, and efficiency are crucial for the overall performance of equipment.

Which Chain Coupling is Recommended for High Torque Loads?

1. Roller Chain Couplings: Roller chain couplings are recommended for high torque loads due to their high torque capacity and shock absorption properties, making them ideal for heavy-duty applications.

2. Grid Couplings: Grid couplings are another suitable option for high torque loads, offering excellent misalignment compensation and durability in demanding industrial environments.

3. Gear Couplings: Gear couplings are designed to handle high torque loads and provide smooth power transmission in steel mills, mining equipment, and other heavy machinery applications.

4. Disc Couplings: Disc couplings are known for their ability to transmit high torque loads with minimal backlash, ensuring precise power transmission and reliable operation in critical applications.

5. Jaw Couplings: Jaw couplings are recommended for applications with high torque requirements, offering easy installation, misalignment compensation, and durability in various industrial settings.

About HZPT

As a leading manufacturer and exporter specializing in couplings, HZPT has been providing high-quality products and exceptional service to customers in Europe and the United States for over 16 years. Our commitment to customer satisfaction and product excellence has earned us a strong reputation in the industry.

At HZPT, we prioritize quality, credibility, and innovation in our design and production processes. Our comprehensive quality inspection system ensures that all products meet the highest standards and are certified with CE and TUV certificates.

When you choose HZPT, you can expect factory-direct pricing, 24-hour customer service, and customization options for OEM and ODM packaging. Our experienced R&D team continuously develops new products to meet market demands and provide our customers with cutting-edge solutions.

Contact us today to learn more about our wide range of couplings, including radial elastic couplings, tire couplings, drum gear couplings, and roller chain couplings, among others. We look forward to establishing successful partnerships with new customers worldwide and delivering the best-in-class products and services.