Introducing Roller Chain Coupling for Woodworking Machinery

1. Durable Material: Roller chain couplings are made from high-quality materials that ensure durability and longevity in woodworking machinery applications.

2. Easy Installation: These couplings are designed for easy installation, saving time and effort during setup in woodworking machinery.

3. Smooth Operation: Roller chain couplings provide smooth operation, reducing vibration and noise in woodworking machinery.

4. High Torque Capacity: With a high torque capacity, roller chain couplings are suitable for heavy-duty woodworking machinery applications.

5. Low Maintenance: These couplings require minimal maintenance, making them a cost-effective choice for woodworking machinery.

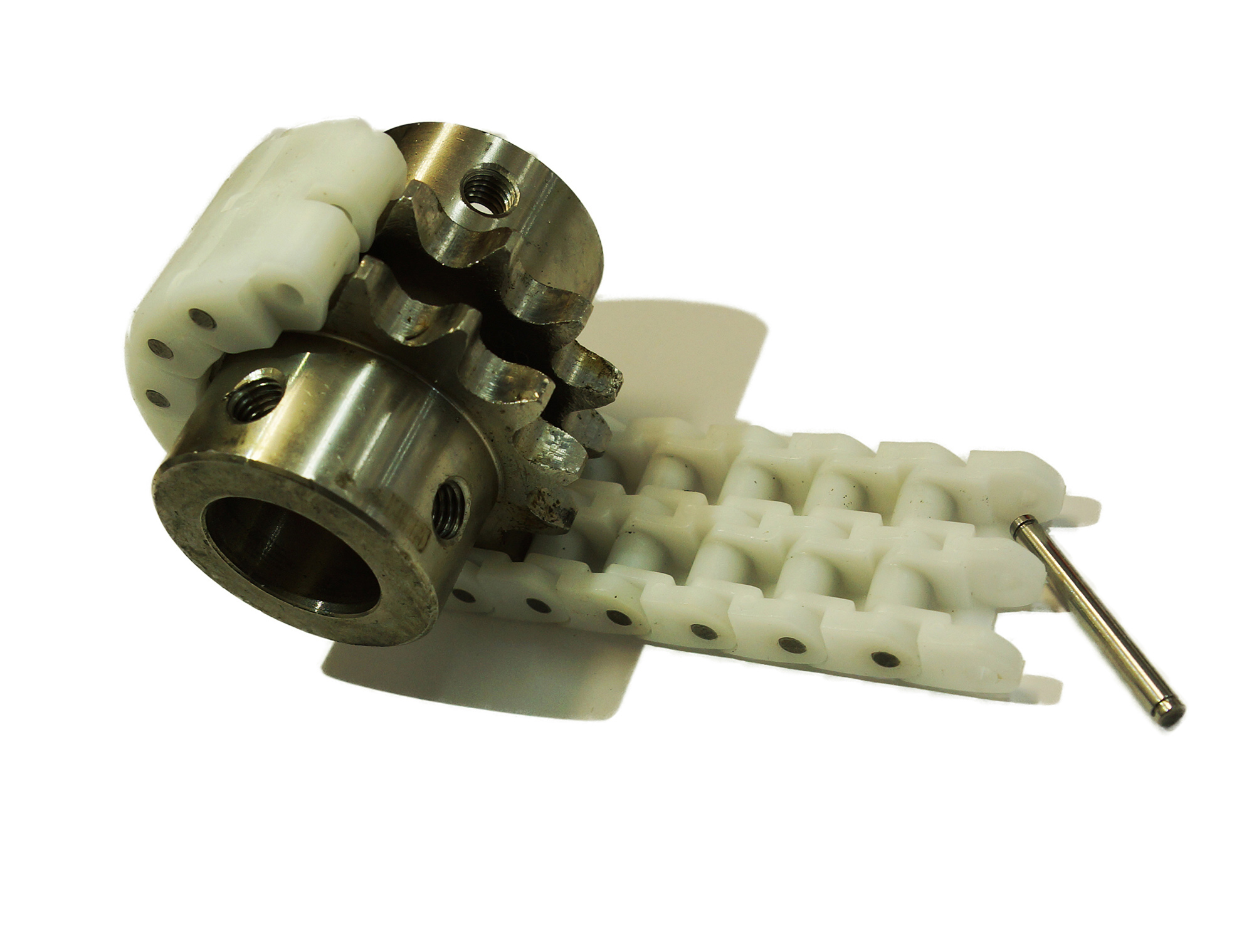

What is a Roller Chain Coupling?

1. Design: A roller chain coupling consists of two sprockets connected by a roller chain, allowing for torque transmission between shafts.

2. Functionality: This coupling type is used to transmit power and motion in woodworking machinery, providing a reliable connection between shafts.

3. Versatility: Roller chain couplings are versatile and can accommodate misalignment, making them ideal for various woodworking machinery applications.

4. Efficiency: These couplings offer high efficiency in power transmission, ensuring optimal performance in woodworking machinery.

5. Benefits: The benefits of using roller chain couplings include durability, ease of installation, smooth operation, and low maintenance requirements.

What are the Advantages of Roller Chain Coupling?

1. High Strength: Roller chain couplings are known for their high strength and durability, making them suitable for heavy-duty woodworking machinery.

2. Flexibility: These couplings can accommodate angular and parallel misalignment, providing flexibility in woodworking machinery applications.

3. Shock Absorption: Roller chain couplings offer shock absorption capabilities, reducing stress on machinery components during operation.

4. Cost-Effective: With low maintenance requirements and long service life, roller chain couplings are a cost-effective choice for woodworking machinery.

5. Reliability: These couplings provide a reliable connection between shafts, ensuring consistent performance in woodworking machinery.

Key Applications of Hydraulic Couplings

1. Industrial Machinery: Hydraulic couplings are commonly used in various industrial machinery applications for power transmission.

2. Agricultural Equipment: These couplings are essential in agricultural machinery for driving pumps, conveyors, and other equipment.

3. Construction Machinery: Hydraulic couplings play a vital role in construction machinery, enabling smooth operation and power transmission.

4. Mining Equipment: In the mining industry, hydraulic couplings are used in heavy-duty equipment for reliable power transmission.

5. Marine Applications: Hydraulic couplings are also utilized in marine machinery for propulsion systems and other applications.

When to Use Chain Coupling?

1. High Torque Transmission: Chain couplings are ideal for applications requiring high torque transmission capabilities.

2. Misalignment Tolerance: When dealing with shaft misalignment, chain couplings provide flexibility and accommodate angular misalignment.

3. Heavy-Duty Machinery: Chain couplings are suitable for heavy-duty machinery applications where durability and reliability are essential.

4. Power Transmission: When efficient power transmission is required, chain couplings offer a reliable solution for various machinery.

5. Low Maintenance: For applications that require minimal maintenance, chain couplings are a cost-effective choice for long-term use.

Which Chain Coupling is Recommended for High Torque Loads?

1. Roller Chain Coupling: Roller chain couplings are recommended for high torque loads due to their high strength and durability.

2. Large Chain Size: Using a larger chain size in the coupling can help accommodate higher torque loads in machinery applications.

3. Hardened Steel Components: Couplings with hardened steel components are suitable for handling high torque loads effectively.

4. Multiple Chain Strands: Couplings with multiple chain strands can distribute torque evenly, making them ideal for high torque applications.

5. Custom Solutions: For specific high torque requirements, customized chain couplings can be designed to meet the needs of the application.

About HZPT

HZPT, established in 2006, is a leading manufacturer and exporter specializing in couplings for various industries. With 16 years of experience, our company has a dedicated design and R&D team to create customized solutions for global customers. We prioritize customer satisfaction and offer CE and TUV certified products. Our commitment to quality, competitive pricing, and excellent service has earned us a high reputation in Europe and the United States. Choose HZPT for top-quality couplings and exceptional service.

If you are interested in partnering with us or have any inquiries, feel free to contact us. We look forward to building successful business relationships with customers worldwide.