Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can chain couplings transmit both torque and linear motion?

No, chain couplings are primarily designed to transmit torque between rotating shafts and are not intended for transmitting linear motion. The main function of a chain coupling is to connect two shafts in order to transfer rotational power from one shaft to another.

Chain couplings achieve torque transmission through the engagement of the roller chain with the sprockets on the connected shafts. As the driving sprocket rotates, it imparts rotational motion to the chain, which in turn rotates the driven sprocket connected to the other shaft. This mechanism allows the torque to be transmitted from one shaft to the other.

However, chain couplings do not provide a means for converting or transmitting linear motion. They are not designed to handle axial displacement or linear forces. Attempting to use a chain coupling for transmitting linear motion would result in inefficient and unreliable operation, as the coupling is not designed to handle the specific requirements and forces associated with linear motion.

For applications that require the transmission of linear motion, there are other types of couplings specifically designed for this purpose. Examples include rack and pinion systems, linear couplings, or specialized linear motion couplings that incorporate mechanisms such as ball screws or lead screws. These couplings are designed to convert rotary motion into linear motion or to transmit linear forces directly.

It is important to select the appropriate coupling type based on the specific requirements of the application, whether it involves torque transmission or the transmission of linear motion. Consulting the manufacturer’s specifications, guidelines, or seeking expert advice can help ensure the correct coupling selection for a particular application.

How to install a chain coupling?

Proper installation of a chain coupling is crucial for ensuring its optimal performance and longevity. Here are the steps to follow when installing a chain coupling:

-

Prepare the Work Area: Before beginning the installation, ensure that the work area is clean and free from any debris or contaminants. This will help prevent any damage to the coupling components during installation.

-

Inspect the Components: Carefully inspect the chain coupling components, including the sprockets, roller chain, connecting pins, and bushings or bearings. Check for any signs of damage or wear. Replace any components that are worn or damaged.

-

Position the Coupling: Position the coupling on the shafts that need to be connected. Ensure that the shafts are aligned properly and the coupling is centered between them.

-

Install the Sprockets: Slide the sprockets onto the shafts, with the teeth facing each other. Make sure the sprockets are securely seated on the shafts and aligned with each other.

-

Connect the Roller Chain: Loop the roller chain around the sprockets, ensuring that it is properly engaged with the sprocket teeth. Connect the ends of the roller chain using the connecting pins. Insert the connecting pins through the pin holes in the chain links and secure them with retaining clips or other fasteners.

-

Tension the Chain: Adjust the tension of the roller chain to the manufacturer’s specifications. The chain should have the appropriate amount of slack to allow for smooth operation and accommodate misalignment but should not be too loose or too tight. Follow the manufacturer’s guidelines for determining the correct chain tension.

-

Secure the Bushings or Bearings: If the chain coupling uses bushings or bearings, ensure they are properly installed in the bores of the sprockets and provide a secure and smooth rotation of the shafts.

-

Apply Lubrication: Apply the recommended lubricant to the roller chain and sprockets. Proper lubrication is essential for reducing friction, wear, and noise, and it helps ensure smooth operation of the chain coupling.

-

Check Alignment and Rotation: Once the chain coupling is installed, check the alignment of the shafts and the rotation of the coupling. Verify that the coupling rotates smoothly without any binding or interference.

-

Inspect and Test: After installation, thoroughly inspect the entire chain coupling assembly. Look for any signs of misalignment, unusual noise, or vibration. Test the coupling’s operation by running the machinery at a low speed and gradually increasing to the normal operating speed. Monitor the coupling for any issues or abnormalities.

Following these installation steps will help ensure a proper and secure installation of the chain coupling, promoting efficient power transmission and minimizing the risk of premature failure or damage.

What is a chain coupling?

A chain coupling is a mechanical device used to connect two rotating shafts in a power transmission system. It consists of two sprockets or toothed wheels and a roller chain that meshes with the sprocket teeth. The sprockets are mounted on the respective shafts and linked together by the chain, allowing torque to be transmitted from one shaft to the other.

Chain couplings are designed to provide a flexible and reliable connection between shafts while accommodating misalignment between them. They are known for their ability to compensate for angular, parallel, and axial misalignments, making them suitable for a wide range of industrial applications.

The sprockets of a chain coupling typically have hardened teeth that engage with the rollers of the chain. The chain itself is made up of a series of interconnected links, each consisting of two plates joined by pins. The rollers are mounted on the pins, allowing them to rotate freely and mesh with the sprocket teeth.

One of the key advantages of chain couplings is their ability to transmit high torque loads. The engagement between the sprockets and the chain provides a positive drive, allowing for efficient power transfer even in demanding applications. Chain couplings are commonly used in heavy-duty machinery and equipment where large amounts of power need to be transferred, such as conveyors, mixers, crushers, and industrial drives.

Chain couplings also offer flexibility in shaft alignment. They can compensate for angular misalignment, which occurs when the shafts are not perfectly aligned at an angle. Additionally, they can accommodate parallel misalignment, where the shafts are offset from each other, as well as axial misalignment, which refers to the displacement along the axis of the shafts.

Proper lubrication is essential for the efficient operation and longevity of chain couplings. Lubricants such as oil or grease are applied to the chain and sprockets to reduce friction and wear. This helps to prevent heat buildup and ensures smooth rotation and power transmission.

Chain couplings are available in various sizes, configurations, and materials to suit different application requirements. The selection of a chain coupling depends on factors such as torque capacity, speed, shaft diameter, and misalignment tolerance.

In summary, chain couplings provide a flexible, reliable, and high-torque solution for connecting rotating shafts in power transmission systems. They offer the ability to compensate for misalignment, making them suitable for a wide range of industrial applications where efficient power transfer is crucial.

editor by CX 2024-05-17

China wholesaler Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling

Product Description

Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling

Features

Material: cast iron GG25, GG20 steel: C45

Parts: 2 couplings and 1 tire body.

Size from F40-F250. and Type: “B”, “F”, “H”.

Working temp: -20~80ºC

Transmission torque:10-20000N.M

Axial misalignment: D*2%

Radial deviation: D*1%

Angular misalignment:3°-6°

Application: tire couplings are usually used in wet, dusty, under attract, vibration, rotating, and complex working conditions. like: diesel pump

Installation: easy on, easy off.

Maintenance: no need for lubricating and durability.

Product Description

| Size | Type | Bush No. | MaxBore | Type F&H | Type H | Serve over Key |

A | C | D | F | M | |||

| mm | Inch | L | E | L | E | |||||||||

| F40 | B | – | 32 | – | – | – | 33 | 22 | M5 | 104 | 82 | – | – | 11 |

| F40 | F | 1008 | 25 | 1″ | 33 | 22 | – | – | – | 104 | 82 | – | – | 11 |

| F40 | H | 1008 | 25 | 1″ | 33 | 22 | – | – | – | 104 | 82 | – | – | 11 |

| F50 | B | – | 38 | – | – | – | 43 | 32 | M5 | 133 | 100 | 79 | – | 12.5 |

| F50 | F | 1210 | 32 | 1 1/4″ | 38 | 25 | – | – | – | 133 | 100 | 79 | – | 12.5 |

| F50 | H | 1210 | 32 | 1 1/4″ | 38 | 25 | – | – | – | 133 | 100 | 79 | – | 12.5 |

| F80 | B | – | 45 | – | – | – | 55 | 33 | M6 | 165 | 125 | 70 | – | 16.5 |

| F80 | F | 1610 | 42 | 1 5/8″ | 42 | 25 | – | – | – | 165 | 125 | 103 | – | 16.5 |

| F60 | H | 1610 | 42 | 1 5/8″ | 42 | 25 | – | – | – | 165 | 125 | 103 | – | 16.6 |

| F70 | B | – | 50 | – | – | – | 47 | 35 | M8 | 187 | 142 | 80 | 60 | 11.5 |

| F70 | F | 2012 | 50 | 2″ | 44 | 32 | – | – | – | 187 | 142 | 80 | 50 | 11.5 |

| F70 | H | 1810 | 42 | 1 5/8″ | 42 | 25 | – | – | – | 187 | 142 | 80 | 50 | 11.5 |

| F80 | B | – | 60 | – | – | – | 55 | 42 | M8 | 211 | 165 | 98 | 54 | 12.5 |

| F80 | F | 2517 | 80 | 2 1/2″ | 58 | 45 | – | – | – | 211 | 165 | 98 | 54 | 12.5 |

| F80 | H | 2012 | 50 | 2″ | 45 | 32 | – | – | – | 211 | 165 | 98 | 54 | 12.5 |

| F90 | H | – | 70 | – | – | – | 63.5 | 49 | M10 | 235 | 188 | 108 | 62 | 13.5 |

| F90 | F | 2517 | 60 | 2 1/2″ | 58.5 | 45 | – | – | – | 235 | 188 | 108 | 62 | 13.5 |

| F90 | H | 2517 | 60 | 2 1/2″ | 58.5 | 45 | – | – | – | 235 | 188 | 108 | 62 | 13.5 |

| F100 | H | – | 80 | – | – | – | 63.5 | 49 | M10 | 235 | 188 | 120 | 62 | 13.5 |

| F100 | F | 3571 | 75 | 3″ | 64.5 | 51 | – | – | – | 235 | 188 | 125 | 62 | 13.5 |

| F100 | H | 2517 | 60 | 2 1/2″ | 58.5 | 45 | – | – | – | 235 | 188 | 113 | 62 | 13.5 |

| F110 | B | – | 90 | – | – | – | 75.5 | 63 | M12 | 279 | 233 | 128 | 62 | 12.5 |

| F110 | F | 3571 | 75 | 3″ | 63.5 | 51 | – | – | – | 279 | 233 | 134 | 62 | 12.5 |

| F110 | H | 3571 | 75 | 3″ | 63.5 | 51 | – | – | – | 279 | 233 | 134 | 62 | 12.5 |

| F120 | B | – | 100 | – | – | – | 84.5 | 70 | M12 | 314 | 264 | 140 | 67 | 14.5 |

| F120 | F | 3525 | 100 | 4″ | 79.5 | 65 | – | – | – | 314 | 264 | 144 | 67 | 14.5 |

| F120 | H | 3571 | 75 | 4″ | 85.5 | 51 | – | – | – | 314 | 264 | 144 | 67 | 14.5 |

| F140 | B | – | 130 | – | – | – | 110.5 | 4 | M16 | 359 | 311 | 178 | 73 | 16 |

| F140 | F | 3525 | 100 | 4″ | 81.5 | 65 | – | – | – | 359 | 311 | 178 | 73 | 16 |

| F140 | H | 3525 | 100 | 4″ | 81.5 | 65 | – | – | – | 359 | 311 | 178 | 73 | 18 |

| F160 | B | – | 140 | – | – | – | 117 | 102 | M20 | 402 | 345 | 187 | 78 | 16 |

| F160 | F | 4030 | 115 | 4 1/2″ | 92 | 77 | – | – | – | 402 | 345 | 197 | 78 | 16 |

| F160 | H | 4030 | 115 | 4 1/2″ | 92 | 77 | – | – | – | 402 | 345 | 197 | 78 | 16 |

| F180 | B | – | 150 | – | – | – | 137 | 114 | M16 | 470 | 394 | 205 | 94 | 23 |

| F180 | F | 4536 | 125 | 5″ | 112 | 89 | – | – | – | 470 | 394 | 205 | 94 | 23 |

| F180 | H | 4535 | 125 | 5″ | 112 | 89 | – | – | – | 470 | 394 | 205 | 94 | 23 |

| F200 | B | – | 150 | – | – | – | 138 | 114 | M20 | 508 | 429 | 205 | 103 | 24 |

| F200 | F | 4535 | 125 | 5″ | 113 | 89 | – | – | – | 508 | 429 | 205 | 103 | 24 |

| F200 | H | 4535 | 125 | 5″ | 113 | 89 | – | – | 508 | 429 | 205 | 103 | 24 | |

| F220 | B | – | 160 | – | – | – | 154.5 | 127 | M20 | 562 | 474 | 223 | 118 | 27.5 |

| F220 | F | 5571 | 125 | 5″ | 129.5 | 102 | – | – | – | 562 | 474 | 223 | 118 | 27.5 |

| F220 | H | 5571 | 125 | 5″ | 129.5 | 102 | – | – | – | 562 | 474 | 223 | 118 | 27.5 |

| F250 | H | – | 190 | – | – | 161.5 | 132 | M20 | 628 | 522 | 254 | 125 | 29.5 | |

Related Products

Company Profile

FAQ

Q: How to ship to us?

A: It is available by air, sea, or train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

What are the common materials used in chain couplings?

Chain couplings are commonly made from various materials that offer the necessary strength, durability, and wear resistance required for transmitting torque between shafts. The choice of materials depends on factors such as the application requirements, operating conditions, and the specific design of the coupling. Here are some common materials used in chain couplings:

- Steel: Steel is one of the most widely used materials for chain couplings. It offers excellent strength, toughness, and resistance to wear and fatigue. Carbon steel and alloy steel are commonly used, with alloy steel providing enhanced properties such as higher tensile strength and improved corrosion resistance.

- Stainless Steel: Stainless steel is chosen for chain couplings when corrosion resistance is a critical requirement. It offers good mechanical properties along with resistance to rust and corrosion, making it suitable for applications in harsh environments or where exposure to moisture or chemicals is present.

- Cast Iron: Cast iron is occasionally used for chain couplings, particularly in applications where cost-effectiveness and moderate strength are important factors. Cast iron provides good wear resistance and can withstand moderate loads and operating conditions.

- Bronze: Bronze is utilized in certain specialized chain couplings, especially in applications where self-lubrication and high resistance to corrosion are required. Bronze has good friction properties and can operate in conditions where lubrication may be limited or unavailable.

- Plastics: In some cases, certain plastics, such as nylon or polyurethane, are used for chain coupling components like chain guides or protective covers. Plastics offer low friction, noise reduction, and resistance to chemicals, making them suitable for specific applications.

It’s important to note that the materials used in chain couplings may vary depending on the specific manufacturer, coupling design, and application requirements. It is recommended to consult the manufacturer’s specifications and guidelines to determine the appropriate materials for a particular chain coupling.

Additionally, in some cases, chain couplings may incorporate a combination of different materials, such as steel for the sprockets and roller chain, and elastomers for the flexible elements. This hybrid construction allows for optimized performance, balancing strength, flexibility, and damping characteristics.

Overall, the selection of materials for chain couplings is crucial to ensure reliable and efficient power transmission while considering factors such as load capacity, operating conditions, and the desired service life of the coupling.

What are the maintenance requirements for chain couplings?

Maintaining chain couplings is essential for their reliable and efficient operation over time. Regular maintenance helps prevent premature wear, reduces the risk of unexpected failures, and prolongs the lifespan of the coupling. Here are some key maintenance requirements for chain couplings:

- Lubrication: Proper lubrication is crucial for the smooth operation of chain couplings. Regularly lubricate the roller chain and sprockets with the recommended lubricant. Follow the manufacturer’s guidelines regarding the type of lubricant to use and the frequency of lubrication. Lubrication helps reduce friction, wear, and noise, and it extends the service life of the coupling.

- Inspection: Regularly inspect the chain coupling for signs of wear, damage, or misalignment. Check the sprockets, roller chain, connecting pins, and bushings or bearings for any abnormalities. Look for worn teeth, elongation of the roller chain, loose or missing fasteners, and excessive play in the coupling. Address any issues promptly to prevent further damage and ensure the coupling’s proper functioning.

- Tension Adjustment: Check the tension of the roller chain regularly. Improper chain tension can lead to premature wear and affect the coupling’s performance. Follow the manufacturer’s guidelines for the correct chain tension and make adjustments as necessary. Proper tension ensures optimal power transmission and helps accommodate misalignments.

- Alignment: Monitor the alignment of the shafts connected by the chain coupling. Misalignment can cause excessive stress on the coupling components and lead to premature failure. If misalignment is detected, take the necessary corrective measures, such as realigning the shafts or using alignment tools. Proper alignment promotes smooth operation and prolongs the life of the coupling.

- Contamination Control: Protect the chain coupling from contamination by keeping the surrounding area clean. Dust, dirt, debris, and moisture can affect the coupling’s performance and accelerate wear. Use appropriate covers or guards to shield the coupling from external contaminants. Regularly clean the coupling and remove any debris that may have accumulated.

- Periodic Replacement: Over time, the components of a chain coupling can experience wear and fatigue. Periodically replace worn or damaged components, such as sprockets, roller chains, connecting pins, and bushings or bearings, with new ones. Follow the manufacturer’s recommended maintenance schedule for component replacement to ensure the coupling’s reliability and prevent unexpected failures.

- Documentation: Maintain proper documentation of the maintenance activities performed on the chain coupling. Keep records of lubrication schedules, inspections, adjustments, and component replacements. This documentation helps track the maintenance history of the coupling and provides valuable information for future reference and troubleshooting.

By following these maintenance requirements, you can ensure the optimal performance, longevity, and reliability of your chain coupling. Regular maintenance minimizes the risk of unexpected downtime, reduces repair costs, and maximizes the efficiency of your machinery or equipment.

What are the different types of chain couplings available?

Chain couplings come in various designs and configurations to suit different application requirements. Here are some common types of chain couplings:

- Standard Roller Chain Couplings: These are the most basic and widely used type of chain couplings. They consist of two sprockets connected by a roller chain. The sprockets have hardened teeth that engage with the chain rollers, providing a reliable power transmission. Standard roller chain couplings are generally suitable for applications with moderate torque and speed requirements.

- Double Roller Chain Couplings: Double roller chain couplings are similar to standard roller chain couplings but feature two parallel roller chains instead of one. This design increases the torque capacity and allows for higher power transmission. Double roller chain couplings are often used in applications that require higher torque and increased load-bearing capabilities.

- Silent Chain Couplings: Silent chain couplings, also known as inverted-tooth chain couplings, use a special toothed chain with a meshing sprocket design. The teeth of the chain engage with the sprocket grooves, providing a smooth and quiet operation. Silent chain couplings are commonly used in applications where noise reduction is important, such as precision machinery or equipment operating in noise-sensitive environments.

- Heavy-Duty Chain Couplings: Heavy-duty chain couplings are designed for applications that demand robust and rugged performance. They are constructed with larger sprockets and heavy-duty roller chains to handle high torque and heavy loads. These couplings are commonly used in industries such as mining, steel, and paper manufacturing, where extreme operating conditions and heavy machinery are present.

- Flexible Chain Couplings: Flexible chain couplings incorporate an elastomeric element, such as a rubber or polyurethane insert, between the sprockets and the chain. This element provides flexibility, damping, and some degree of misalignment compensation. Flexible chain couplings are suitable for applications that require shock absorption, vibration damping, and moderate misalignment tolerance.

- Stainless Steel Chain Couplings: Stainless steel chain couplings are specifically designed for applications that require corrosion resistance and sanitation, such as food processing, pharmaceutical, and chemical industries. They are made of stainless steel or other non-corrosive materials to withstand harsh environments and maintain hygienic conditions.

These are just a few examples of the different types of chain couplings available. Each type has its own advantages and is suitable for specific application requirements. It is important to carefully consider the torque, speed, misalignment, environmental factors, and other application-specific needs when selecting the appropriate chain coupling type for your particular application.

editor by CX 2023-09-28

China high quality Flexible Flex Fluid Chain Jaw Flange Gear Rigid Spacer Pin HRC Mh Nm Universal Fenaflex Oldham Spline Clamp Tyre Grid Hydraulic Servo Motor Shaft Coupling

Product Description

Flexible flex Fluid Chain Jaw flange Gear Rigid Spacer PIN HRC MH NM universal Fenaflex Oldham spline clamp tyre grid hydraulic servo motor shaft Coupling

Product Description

The function of Shaft coupling:

1. Shafts for connecting separately manufactured units such as motors and generators.

2. If any axis is misaligned.

3. Provides mechanical flexibility.

4. Absorb the transmission of impact load.

5. Prevent overload

We can provide the following couplings.

| Rigid coupling | Flange coupling | Oldham coupling |

| Sleeve or muff coupling | Gear coupling | Bellow coupling |

| Split muff coupling | Flexible coupling | Fluid coupling |

| Clamp or split-muff or compression coupling | Universal coupling | Variable speed coupling |

| Bushed pin-type coupling | Diaphragm coupling | Constant speed coupling |

Company Profile

We are an industrial company specializing in the production of couplings. It has 3 branches: steel casting, forging, and heat treatment. Main products: cross shaft universal coupling, drum gear coupling, non-metallic elastic element coupling, rigid coupling, etc.

The company mainly produces the industry standard JB3241-91 swap JB5513-91 swc. JB3242-93 swz series universal coupling with spider type. It can also design and produce various non-standard universal couplings, other couplings, and mechanical products for users according to special requirements. Currently, the products are mainly sold to major steel companies at home and abroad, the metallurgical steel rolling industry, and leading engine manufacturers, with an annual production capacity of more than 7000 sets.

The company’s quality policy is “quality for survival, variety for development.” In August 2000, the national quality system certification authority audited that its quality assurance system met the requirements of GB/T19002-1994 IDT ISO9002:1994 and obtained the quality system certification certificate with the registration number 0900B5711. It is the first enterprise in the coupling production industry in HangZhou City that passed the ISO9002 quality and constitution certification.

The company pursues the business purpose of “reliable quality, the supremacy of reputation, commitment to business and customer satisfaction” and welcomes customers at home and abroad to choose our products.

At the same time, the company has established long-term cooperative relations with many enterprises and warmly welcomes friends from all walks of life to visit, investigate and negotiate business!

How to use the coupling safely

The coupling is an intermediate connecting part of each motion mechanism, which directly impacts the regular operation of each motion mechanism. Therefore, attention must be paid to:

1. The coupling is not allowed to have more than the specified axis deflection and radial displacement so as not to affect its transmission performance.

2. The bolts of the LINS coupling shall not be loose or damaged.

3. Gear coupling and cross slide coupling shall be lubricated regularly, and lubricating grease shall be added every 2-3 months to avoid severe wear of gear teeth and serious consequences.

4. The tooth width contact length of gear coupling shall not be less than 70%; Its axial displacement shall not be more significant than 5mm

5. The coupling is not allowed to have cracks. If there are cracks, it needs to be replaced (they can be knocked with a small hammer and judged according to the sound).

6. The keys of LINS coupling shall be closely matched and shall not be loosened.

7. The tooth thickness of the gear coupling is worn. When the lifting mechanism exceeds 15% of the original tooth thickness, the operating mechanism exceeds 25%, and the broken tooth is also scrapped.

8. If the elastic ring of the pin coupling and the sealing ring of the gear coupling is damaged or aged, they should be replaced in time.

Certifications

Packaging & Shipping

How does the chain size affect the performance of a chain coupling?

The chain size has a significant impact on the performance of a chain coupling. The size of the chain refers to the physical dimensions of the roller chain used in the coupling, including the pitch, roller diameter, and width. Here are some key ways in which the chain size affects the performance of a chain coupling:

- Torque Capacity: The chain size directly affects the torque capacity of the chain coupling. Larger chain sizes are generally capable of transmitting higher torque loads due to their increased contact area and greater strength. Smaller chain sizes, on the other hand, have lower torque capacities and are suitable for applications with lighter torque requirements.

- Speed Capability: The chain size also influences the speed capability of the chain coupling. Larger chains can typically handle higher rotational speeds without experiencing issues such as excessive vibration or centrifugal forces. Smaller chain sizes may have limitations in terms of maximum allowable speeds and may not be suitable for high-speed applications.

- Service Life: The selection of an appropriate chain size is crucial for achieving the desired service life of the chain coupling. If the chain is undersized for the application, it may experience premature wear, fatigue, and ultimately fail under the operating conditions. Conversely, using an oversized chain may result in unnecessary costs, increased weight, and reduced efficiency.

- Space Constraints: The physical size of the chain can also impact the overall dimensions and installation requirements of the chain coupling. Larger chain sizes may require more space for proper installation, including clearance for the chain links and sprockets. In applications with limited space, choosing a smaller chain size may be necessary to ensure proper fit and operation.

- Compatibility: The chain size should be compatible with the sprockets and other components of the chain coupling. It is important to ensure that the chain and sprockets are designed to work together, with matching dimensions and tooth profiles. Using an incompatible chain size can lead to poor engagement, increased wear, and reduced overall performance.

When selecting the appropriate chain size for a chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, space limitations, and compatibility with other components. Consulting the manufacturer’s recommendations and guidelines is crucial to ensure the optimal chain size selection for the desired performance, reliability, and longevity of the chain coupling.

How to install a chain coupling?

Proper installation of a chain coupling is crucial for ensuring its optimal performance and longevity. Here are the steps to follow when installing a chain coupling:

-

Prepare the Work Area: Before beginning the installation, ensure that the work area is clean and free from any debris or contaminants. This will help prevent any damage to the coupling components during installation.

-

Inspect the Components: Carefully inspect the chain coupling components, including the sprockets, roller chain, connecting pins, and bushings or bearings. Check for any signs of damage or wear. Replace any components that are worn or damaged.

-

Position the Coupling: Position the coupling on the shafts that need to be connected. Ensure that the shafts are aligned properly and the coupling is centered between them.

-

Install the Sprockets: Slide the sprockets onto the shafts, with the teeth facing each other. Make sure the sprockets are securely seated on the shafts and aligned with each other.

-

Connect the Roller Chain: Loop the roller chain around the sprockets, ensuring that it is properly engaged with the sprocket teeth. Connect the ends of the roller chain using the connecting pins. Insert the connecting pins through the pin holes in the chain links and secure them with retaining clips or other fasteners.

-

Tension the Chain: Adjust the tension of the roller chain to the manufacturer’s specifications. The chain should have the appropriate amount of slack to allow for smooth operation and accommodate misalignment but should not be too loose or too tight. Follow the manufacturer’s guidelines for determining the correct chain tension.

-

Secure the Bushings or Bearings: If the chain coupling uses bushings or bearings, ensure they are properly installed in the bores of the sprockets and provide a secure and smooth rotation of the shafts.

-

Apply Lubrication: Apply the recommended lubricant to the roller chain and sprockets. Proper lubrication is essential for reducing friction, wear, and noise, and it helps ensure smooth operation of the chain coupling.

-

Check Alignment and Rotation: Once the chain coupling is installed, check the alignment of the shafts and the rotation of the coupling. Verify that the coupling rotates smoothly without any binding or interference.

-

Inspect and Test: After installation, thoroughly inspect the entire chain coupling assembly. Look for any signs of misalignment, unusual noise, or vibration. Test the coupling’s operation by running the machinery at a low speed and gradually increasing to the normal operating speed. Monitor the coupling for any issues or abnormalities.

Following these installation steps will help ensure a proper and secure installation of the chain coupling, promoting efficient power transmission and minimizing the risk of premature failure or damage.

What are the advantages of using chain couplings?

-

Flexible and Reliable Connection: Chain couplings provide a flexible and reliable connection between rotating shafts. They can accommodate misalignment between the shafts, including angular, parallel, and axial misalignments. This flexibility helps to reduce stress on the shafts and bearings, resulting in smoother operation and extended equipment lifespan.

-

High Torque Capacity: Chain couplings are capable of transmitting high torque loads. The positive engagement between the sprocket teeth and the chain rollers allows for efficient power transfer, making them suitable for applications that require the transmission of substantial rotational forces.

-

Mechanical Protection: Chain couplings act as mechanical protection by providing a breakable link in the power transmission system. In case of sudden overloads or jams in the system, the chain can break, preventing damage to the machinery components. This feature helps to protect expensive equipment and minimizes downtime for repairs.

-

Misalignment Compensation: Chain couplings can compensate for misalignment between the connected shafts. They can tolerate angular misalignment, where the shafts are not perfectly aligned at an angle, parallel misalignment, where the shafts are offset from each other, and axial misalignment, which refers to displacement along the axis of the shafts. This ability to accommodate misalignment helps to prevent excessive stress and premature wear on the shafts and bearings.

-

Wide Range of Applications: Chain couplings are versatile and find applications in various industries and machinery. They are used in conveyors, pumps, crushers, mixers, industrial drives, and many other systems. The ability to handle different torque requirements, speed variations, and misalignment conditions makes chain couplings suitable for a wide range of power transmission needs.

-

Easy Maintenance: Chain couplings are relatively easy to maintain. Regular lubrication of the chain and sprockets helps to reduce friction and wear, ensuring smooth operation and extending the life of the coupling. Maintenance tasks such as chain tensioning and inspection can be carried out without requiring complex tools or specialized training.

In summary, the advantages of using chain couplings include their flexible and reliable connection, high torque capacity, ability to compensate for misalignment, mechanical protection, wide range of applications, and ease of maintenance. These features make chain couplings a preferred choice in various industries where efficient power transmission and reliable operation are vital.

editor by CX 2023-08-29

China Belt Conveyor Rexnord Oil Hydraulic Coupler Torque Converter Drive Shaft Adapter Spline Flexible Motor Clutch Yox Fluid Coupling coupling connector

Warranty: 3 years

Applicable Industries: Creating Substance Stores, Manufacturing Plant, Machinery Fix Outlets, Vitality & Mining

Tailored assist: OEM, ODM, OBM

Composition: Common

Versatile or Rigid: Adaptable

Normal or Nonstandard: Nonstandard

Content: Metal

color: Customized

Packaging Information: Standard export wood box

Port: China Principal Port

Merchandise Description The hydraulic fluid coupling is a kind of hydraulic transmission device that utilizes the kinetic energy of the liquid to transmit vitality. It utilizes liquid oil as the operating medium, and transforms the mechanical power and the kinetic energy of the liquid via the pump wheel and turbine, so as to link the key mover and the operating machinery to comprehend electrical power transmission. In accordance to its application traits, hydraulic coupler can be divided into 3 fundamental kinds, specifically normal sort, torque limiting type, pace regulating type and 2 by-product sorts: hydraulic fluid coupling transmission system and hydraulic reducer. Fluid coupling is widely utilised in coal mine and ship hoisting and transportation equipment. It can make the transmission electricity of multiple motors exceed the stability, helps prevent the motor from idling, absorbs the vibration in the transmission system, prevents the motor from burning out, and extends the service lifestyle of transmission factors. Fluid couplings are primarily utilised in adaptable scraper conveyor, scraper device, belt conveyor, HYCNC 1.25m 2225671mm Cnc Router Gear Rack Pinion Helical Tooth Cnc Equipment Rack Low-cost Price Manufacturing unit Immediately Market coal plough, transfer device and belt conveyor. The Fluid coupling has easy structure and a collection of outstanding doing work characteristics. YOX variety pump wheel, housing, rear auxiliary chamber, driving joint, driven joint and elastic block are the driving parts, of which the elastic block is a adaptable part with distinct center values for payment and set up, and the turbine and turbine shaft form the driven partFunction of Fluid coupling1. Start off stably and decrease shock and vibration throughout procedure.2. Improve the motor capacity and decrease the influence present of the power grid.3. Overload safety, shield the motor and functioning device from hurt and burning due to overload.4. Shorten the length of current and help save energy.5. The load can be well balanced when several motors are linked in parallel.6. Hydraulic coupling factors have no mechanical use and long provider daily life

Types of Coupling

A coupling is a device used to join two shafts together and transmit power. Its primary function is to join rotating equipment and allows for some end movement and misalignment. This article discusses different types of coupling, including Magnetic coupling and Shaft coupling. This article also includes information on Overload safety mechanical coupling.

Flexible beam coupling

Flexible beam couplings are universal joints that can deal with shafts that are offset or at an angle. They consist of a tube with couplings at both ends and a thin, flexible helix in the middle. This makes them suitable for use in a variety of applications, from motion control in robotics to attaching encoders to shafts.

These couplings are made of one-piece materials and are often made of stainless steel or aluminium alloy. However, they can also be made of acetal or titanium. While titanium and acetal are less common materials, they are still suitable for high-torque applications. For more information about beam couplings, contact CZPT Components.

Flexible beam couplings come in a variety of types and sizes. W series couplings are good for general purpose applications and are relatively economical. Stainless steel versions have increased torque capacity and torsional stiffness. Flexible beam couplings made of aluminum are ideal for servo and reverse motion. They are also available with metric dimensions.

Flexible beam couplings are made of aluminum alloy or stainless steel. Their patented slot pattern provides low bearing load and high torsional rigidity. They have a long operational life. They also require zero maintenance and can handle angular offset. Their advantages outweigh the disadvantages of traditional beam couplings.

Magnetic coupling

Magnetic coupling transfers torque from one shaft to another using a magnetic field. These couplings can be used on various types of machinery. These types of transmissions are very useful in many situations, especially when you need to move large amounts of weight. The magnetic field is also very effective at reducing friction between the two shafts, which can be extremely helpful if you’re moving heavy items or machinery.

Different magnetic couplings can transmit forces either linearly or rotated. Different magnetic couplings have different topologies and can be made to transmit force in various geometric configurations. Some of these types of couplings are based on different types of materials. For example, a ceramic magnetic material can be used for applications requiring high temperature resistance.

Hybrid couplings are also available. They have a hybrid design, which allows them to operate in either an asynchronous or synchronous mode. Hysterloy is an alloy that is easily magnetized and is used in synchronous couplings. A synchronous magnetic coupling produces a coupled magnetic circuit.

Magnetic coupling is a key factor in many physical processes. In a crystal, molecules exhibit different magnetic properties, depending on their atomic configuration. Consequently, different configurations produce different amounts of magnetic coupling. The type of magnetic coupling a molecule exhibits depends on the exchange parameter Kij. This exchange parameter is calculated by using quantum chemical methods.

Magnetic couplings are most commonly used in fluid transfer pump applications, where the drive shaft is hermetically separated from the fluid. Magnetic couplings also help prevent the transmission of vibration and axial or radial loads through the drive shaft. Moreover, they don’t require external power sources, since they use permanent magnets.

Shaft coupling

A shaft coupling is a mechanical device that connects two shafts. The coupling is designed to transmit full power from one shaft to the other, while keeping the shafts in perfect alignment. It should also reduce transmission of shock loads. Ideally, the coupling should be easy to connect and maintain alignment. It should also be free of projecting parts.

The shaft couplings that are used in machines are typically made of two types: universal coupling and CZPT coupling. CZPT couplings are designed to correct for lateral misalignment and are composed of two flanges with tongues and slots. They are usually fitted with pins. The T1 tongue is fitted into flange A, while the T2 tongue fits into flange B.

Another type of shaft coupling is known as a “sliced” coupling. This type of coupling compensates for inevitable shaft misalignments and provides high torque. Machined slits in the coupling’s outer shell help it achieve high torsional stiffness and excellent flexibility. The design allows for varying engagement angles, making it ideal for many different applications.

A shaft coupling is an important component of any machine. Proper alignment of the two shafts is vital to avoid machine breakdowns. If the shafts are misaligned, extra force can be placed on other parts of the machine, causing vibration, noise, and damage to the components. A good coupling should be easy to connect and should ensure precise alignment of the shaft. Ideally, it should also have no projecting parts.

Shaft couplings are designed to tolerate a certain amount of backlash, but it must be within a system’s threshold. Any angular movement of the shaft beyond this angle is considered excessive backlash. Excessive backlash results in excessive wear, stress, and breakage, and may also cause inaccurate alignment readings. It is therefore imperative to reduce backlash before the shaft alignment process.

Overload safety mechanical coupling

Overload safety mechanical couplings are devices that automatically disengage when the torque applied to them exceeds a specified limit. They are an efficient way to protect machinery and reduce the downtime associated with repairing damaged machinery. The advantage of overload couplings is their fast reaction time and ease of installation.

Overload safety mechanical couplings can be used in a wide range of applications. Their automatic coupling mechanisms can be used on any face or edge. In addition, they can be genderless, incorporating both male and female coupling features into a single mechanism. This means that they are both safe and gender-neutral.

Overload safety couplings protect rotating power transmission components from overloads. Overload protection devices are installed on electric motors to cut off power if the current exceeds a certain limit. Likewise, fluid couplings in conveyors are equipped with melting plug elements that allow the fluid to escape when the system becomes too hot. Mechanical force transmission devices, such as shear bolts, are designed with overload protection in mind.

A common design of an overload safety mechanical coupling consists of two or more arms and hubs separated by a plastic spider. Each coupling body has a set torque threshold. Exceeding this threshold may damage the spider or damage the jaws. In addition, the spider tends to dampen vibration and absorb axial extension. This coupling style is nearly backlash free, electrically isolating, and can tolerate very little parallel misalignment.

A mechanical coupling may also be a universal joint or jaw-clutch coupling. Its basic function is to connect the driver and driven shafts, and limits torque transfer. These devices are typically used in heavy-duty industries, such as steel plants and rolling mills. They also work well with industrial conveyor systems.

CZPT Pulley

The CZPT Pulley coupling family offers a comprehensive range of couplings for motors of all types. Not only does this range include standard motor couplings, but also servo couplings, which require ultra-precise control. CZPT Pulley couplings are also suitable for engine applications where high shocks and vibrations are encountered.

CZPT Pulley couplings have a “sliced” body structure, which allows for excellent torsional stiffness and strength. They are corrosion-resistant and can withstand high rotational speeds. The couplings’ design also ensures accurate shaft rotation while limiting shaft misalignment.

CZPT Pulley has introduced the CPU Pin Type couplings, which are effective at damping vibration and maintain zero backlash. They are also made from aluminum and are capable of absorbing heat. They come with recessed tightening screws. They can handle speeds up to 4,000 RPM, and are RoHS-compliant.

editor by czh 2023-02-19

Best China manufacturer & factory china supplier planetary gear reducer hydraulic motor for tower cranes aerial platforms construction equipment With high quality best price

The high precise CNC equipment, such as Slow-feeding wire-cut machine, jig grinding machine and electric discharge machine, ensures the top quality precision of mould processing, with the high efficient and environmental protection acid rolling line being the largest raw material converting equipment in the field in china; The wildly use of automatic milling machine, high-speed automatic feeding punch, high speed automatic rolling and assembling machine guarantees the high quality and efficiency of components and chain making.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Pole:

-

single stage two stage three stage

- Ratio:

-

25-4000

- Housing Material:

-

Cast Iron

- Material:

-

20CrMn

- Working temperature:

-

-40~45℃

- Application:

-

planetary gear reducer hydraulic motor for tower cranes aerial

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

92%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Single direction FREE WHEEL (RA) Single direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT)

Blue,Green,Gray,Red

Supply Ability

- Supply Ability:

- 5000 Set/Sets per Year P Planetary Gear Reducer Gearbox with Electric motor speed

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for planetary gear reducer hydraulic motor for tower cranes aerial platforms construction equipment

- Port

- Qingdao port

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

PROFESSIONAL MANUFACTURE

—— SINCE 1995

NGW / P Series Planetary Gear Reducer

Sun Gear, Planetary Gear,Internal GearRing,Staging Gear

P series Planetary Gear Reducer Gearbox with Electric motor speed reducer

Chinese Speed Reducer widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

NGW Series including one-stage,two-stage and three-stage, it is suitable for the required speed ratio≤1500r/min, working temperature around -40~45℃, two runs alternative in direction.

P series Planetary Gearbox including two-stage aThe company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CAD/CAM system, industrial robot etc. nd three-stage, it is suitable for the required speed ratio 25-4000, the ratio will be larger in combination with R,K series reducer.

Feature:

-

Modular design

- Including Single Stage, Two Stage, Three Stage

-

Material: Cast iron HT 250 for housing; 20CrMnTi for Gear and Shaft

-

Sun gear, Planetary gear and Ring gear all c which will improve the efficiency and service life of the reducer.

-

Input mode: coaxial input, helical gear input, bevel-helical gear input

-

Output mode: internal involute spline, hollow shaft with shrink disk, external involute spline, solid shaft with flat key.

-

Mounting mode: Horizontal,Vertical,Torque-arm

- Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

Specification

P series planetary gear reducer hydraulic motor for tower cranes aerial platforms construction equipment

Mounting Diamensions:

(please contact us for more types & model)

Type:

| Type | Planetary gear units |

| Size | 9-34 |

| Stage | 2 stage 3 stage |

| Ratio | 25-4000 |

| Input mode | coaxial input, helical gear input, bevel helical gear input |

| Output mode | A hollow shaft with shrink disk B solid shaft with parallel key C hollow shaft with involute splines D solid shaft with involute splines |

| Mouting mode | horizontal, vertical, torque arm |

Model selection:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.P series Planetary Gear Reducer Gearbox with Electric motor speed reducer. P series 1400HP forged 17CrNiMo6 20Cr2Ni4 alloy steel planetary gearbox speed reductor

Technology

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical Worm gears are the most compact type of system and provide high-ratio speed reduction. They are often the preferred type of gearing system when space is limited and large gear reductions are needed. Worm gears can be used to either greatly increase torque or greatly reduce speed. They are also the smoothest and quietest of the gear systems, as long as they are properly mounted and lubricated.industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.P series Planetary Gear Reducer Gearbox with Electric motor speed reducer.

Packaging & Shipping

Company Information

Established in 1995 , HangZhou Ever-Power Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “EPG”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look forward to speaking with you to future discuss how we can be of service to you.

FAQ

1.Q:Are you the factory or trading company?

A:We are the Factory, with 25 years of production experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days. Cutomized type need to according to the quantity.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

5.Q:What’s your payment terms?

A:TT 30% as deposite, 70% banlance paid before delivery.

Best China manufacturer & factory Chinese supplier Eaton geroler rail hydraulic motor hydraulic motor with brake motor rail hydraulic motor hydraulic With high quality best price

We are aiming to meet the demands of the clients around the world.. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

1.5 years

- For all frame sizes, housings are made from injected aluminium, which lend this series an optimum performance when used in applications requiring low torque, and an efficiency similar to the one of cast-iron products. After Warranty Service:

-

Online support

- Local Service Location:

-

none

- Showroom Location:

-

none

- Type:

-

parts

- Brand Name:

-

OEM

- Place of Origin:Zhejiang, China

- Pressure:

-

–

- Structure:

-

–

- Certification:

-

–

- Weight:

-

–

- Power(W):

-

–

- Dimension(L*W*H):

-

–

- After-sales Service Provided:

-

Video technical support

- Color:

-

Silver

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport.

Packaging & Delivery

- Packaging Details

- Carton or Plywood case

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 To be negotiated

Online Customization

TECHNICAL DATA

| TYPE | BMP-50 BMPH-50 |

BMP-80 BMPH-80 |

BMP-100 BMPH-100 |

BMP-125 BMPH-125 |

BMP-160 BMPH-160 |

BMP-200 BMPH-200 |

BMP-250 BMPH-250 |

BMP-315 BMPH-315 |

BMP-400 BMPH-400 |

|

| Displcement (ml/r) |

52.9 | 79.3 | 98.2 | 120.9 | 158.7 | 196.4 | 241.8 | 317.3 | 392.9 | |

| Max.Pressure. Drop (Mpa) |

cont. | 14 | 14 | 14 | 14 | 14 | 14 | 12 | 10 | 8 |

| int. | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 14 | 12 | 10 | |

| peak. | 22 | 22 | 22 | 22 | 22 | 22 | 20 | 15 | 13 | |

| Max. torque (N.Mm) |

cont. | 97 | 148 | 183 | 229 | 295 | 364 | 369 | 404 | 416 |

| int. | 125 | 189 | 238 | 292 | 382 | 470 | 444 | 501 | 531 | |

| peak. | 149 | 222 | 276 | 340 | 445 | 532 | 568 | 555 | 596 | |

| Max. Speed (cont.)(r/min) |

755 | 750 | 610 | 490 | 375 | 305 | 245 | 185 | 150 | |

| Max. Flow (cont.)(L/min) |

40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Max. Output. Power (cont.)(Kw) |

6.5 | 10 | 10 | 10 | 10 | 10 | 8 | 7 | 5.7 | |

| Weight(kg) | 5.6 | 5.7 | 5.9 | 6 | 6.2 | 6.4 | 6.6 | 6.9 | 7.4 | |

Intermittent operationSingle direction FREE WHEEL (RA) Single direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT) the permssible values may occur for max. 10% of every minute

Peak load: the permissible values may occur for max.1% of every minute

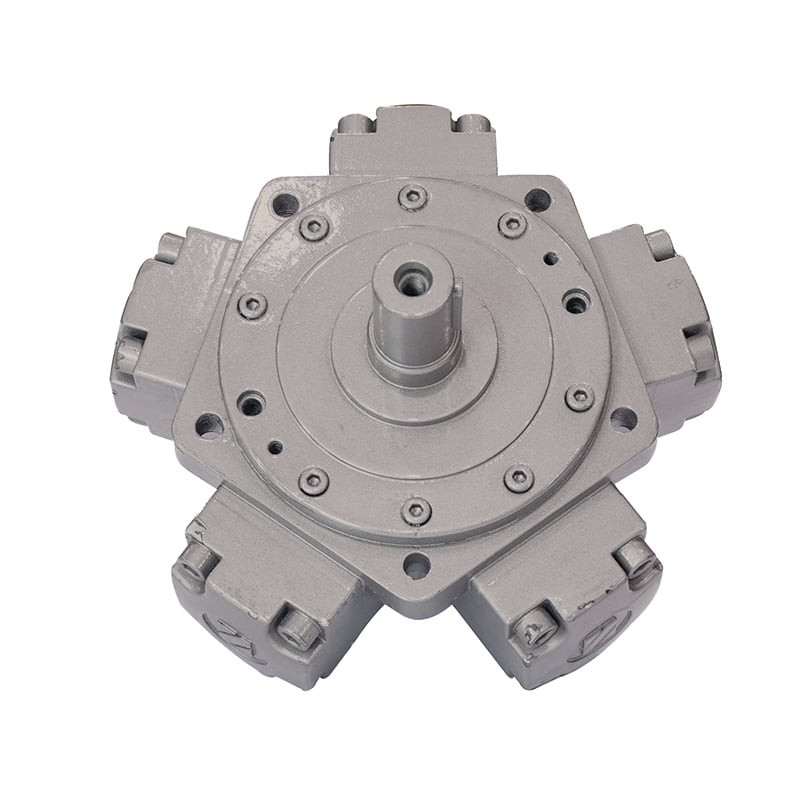

china Lowest price factory supplier radial piston hydraulic motor pump Radial piston hydraulic motor

we offer one-stop resolution for the acquire of mechanical electricity transmission and pto shaft, agricultural gearboxes products in China.

Overview

Quick Specifics

- Issue:

-

New

- Warranty:

-

one.five a long time

- After Guarantee Service:

-

Movie specialized assistance

- Nearby Services Location:

-

Egypt

- Showroom Place:

-

Egypt

- Type:

-

areas

- Brand Name:

-

OEM

- Place of Origin:Zhejiang, China

- Pressure:

-

hydraulic stress

- Framework:

-

hydraulic technique, 5 Radial Piston Motor

- Certification:

-

CE

- Weight:

-

≤75kg

- Power(W):

-

6000-90000

- Following-product sales Service Presented:

-

Online video technical assistance

Source Capacity

- Offer Ability:

- 5000 Piece/Pieces per Thirty day period radial piston hydraulic motor pump

Packaging & Supply

- Packaging Information

- packaged in plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Guide Time

: -

Quantity(Baggage) 1 – twenty >20 Est. Time(days) fifteen To be negotiated

On-line Customization

| Type | Displacement (ml/r) |

Strain (Mpa) |

Torque(N.m) | Pace Selection (r/min) |

Max.cont. Power (kw) |

Excess weight (kg) |

||

| (N.m) Charge torque |

N.m/Mpa Theoric Torque |

|||||||

| peak stress | cont.strain | |||||||

| JMDG1-50 | fifty four | 24 | twenty | 164 | eight | 35-500 | 6 | 23 |

| JMDG1-sixty three | sixty four | 24 | 20 | 188 | 9 | 35-500 | 7 | 23 |

| JMDG1-80 | seventy eight | 22 | eighteen | 206 | 11 | 35-five hundred | 9 | 23 |

| JMDG1-one hundred | ninety six | 22 | 18 | 253 | fourteen | 35-500 | eleven | 23 |

| JMDG1-a hundred twenty five | 126 | 22 | 18 | 332 | eighteen | 35-500 | 15 | 23 |

| JMDG1-a hundred and sixty | 159 | twenty | 16 | 373 | 23 | 35-five hundred | 16 | 23 |

| JMDG2-one hundred | 113 | 24 | 20 | 331 | seventeen | thirty-four hundred | eleven | 28 |

| JMDG2-one hundred fifty | 157 | 24 | 20 | 460 | 23 | 30-four hundred | fifteen | 28 |

| JMDG2-one hundred seventy five | 176 | 22 | eighteen | 464 | 26 | thirty-four hundred | seventeen | 28 |

| JMDG2-200 | 201 | 22 | 18 | 530 | 29 | 30-four hundred | 19 | 28 |

| JMDG2-250 | 254 | 20 | sixteen | 595 | 37 | 30-400 | 21 | 28 |

| JMDG2-280 | 271 | 20 | 16 | 635 | 39 | 30-four hundred | 23 | 28 |

| JMDG3-200 | 199 | 22 | eighteen | 525 | 29 | thirty-350 | 25 | 36 |

| JMDG3-250 | 254 | 22 | 18 | 670 | 37 | 30-350 | 32 | 36 |

| JMDG3-three hundred | 289 | 22 | eighteen | 762 | forty two | thirty-350 | 32 | 36 |

| JMDG3-350 | 351 | 22 | eighteen | 926 | 51 | thirty-350 | 32 | 36 |

| JMDG3-four hundred | 397 | twenty | sixteen | 931 | fifty eight | thirty-350 | 32 | 36 |

| JMDG3-450 | 462 | 20 | sixteen | 1083 | 68 | 30-350 | 32 | 36 |

| JMDG6-400 | 397 | 22 | 18 | 1047 | fifty eight | 25-320 | forty six | sixty five |

| JMDG6-450 | 452 | 22 | 18 | 1192 | 66 | twenty five-320 | 53 | 65 |

| JMDG6-five hundred | 491 | 22 | 18 | 1295 | seventy two | 25-320 | 53 | sixty five |

| JMDG6-600 | 594 | 22 | eighteen | 1566 | 87 | 25-320 | 63 | 65 |

| JMDG6-seven-hundred | 683 | 22 | 18 | 1801 | a hundred | twenty five-320 | sixty three | 65 |

| JMDG6-750 | 754 | 20 | sixteen | 1767 | a hundred and ten | twenty five-320 | sixty three | sixty five |

| JMDG6-800 | 799 | twenty | 16 | 1873 | 117 | twenty five-320 | 63 | sixty five |

| JMDG8-600 | 617 | 22 | 18 | 1627 | ninety | 20-280 | 80 | 71 |

| JMDG8-seven hundred | 710 | 22 | eighteen | 1872 | 104 | twenty-280 | 80 | seventy one |

| JMDG8-800 | 810 | 22 | eighteen | 2136 | 118 | 20-280 | 85 | 71 |

| JMDG8-900 | 889 | twenty | sixteen | 2084 | one hundred thirty | 20-280 | eighty five | seventy one |

| JMDG8-1000 | a thousand | 20 | sixteen | 2344 | 146 | 20-280 | 85 | seventy one |

| JMDG8Y-700 | 710 | 24 | twenty | 2080 | 101 | 20-280 | 85 | 75 |

| JMDG8Y-800 | 810 | 24 | 20 | 2373 | 116 | twenty-280 | eighty five | seventy five |

| JMDG8Y-900 | 889 | 24 | twenty | 2604 | 127 | twenty-280 | eighty five | 75 |

| JMDG8Y-a thousand | one thousand | 24 | twenty | 2930 | 143 | 20-280 | 85 | 75 |

| JMDG8Y-1100 | 1117 | 22 | eighteen | 2945 | one hundred sixty | twenty-280 | 90 | 75 |

| JMDG8Y-1200 | 1178 | 22 | 18 | 3106 | 168 | 20-280 | 90 | 75 |