Product Description

Product Description

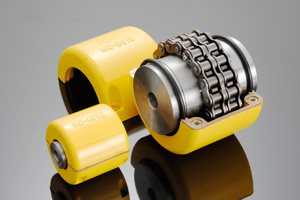

We are offering a wide range of Chain Coupling to our respected clients. Our offered products are used to join 2 pieces of rotating equipment while permitting the various degree of misalignment or end movement or both. Moreover, by careful installation and maintenance of couplings, substantial savings can be made in reduced downtime and maintenance costs.

Packaging & Shipping

Company Profile

FAQ

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

Accommodating Misalignment and Reliable Torque Transmission in Roller Chain Couplings

Roller chain couplings are designed to accommodate misalignment and provide reliable torque transmission in mechanical power transmission systems. They achieve this through the following features:

- Elongated Holes: The roller chain coupling’s hubs have elongated holes that allow for angular misalignment between the connected shafts. These holes provide flexibility and prevent excessive stress on the coupling and connected equipment.

- Roller Chain Design: The roller chain used in the coupling is a flexible and robust component that can transmit torque even in situations with slight misalignment. The design of the roller chain ensures smooth engagement and disengagement of the sprockets, reducing wear and power loss.

- Tension Adjustment: Roller chain couplings typically have an adjusting mechanism that allows for tensioning the chain. Proper tensioning is crucial for maintaining efficient torque transmission and preventing slippage.

- Single or Double Roller Chain: Some roller chain couplings come with a double roller chain design, which increases the torque capacity and allows for higher misalignment compensation.

- Torsionally Rigid Coupling: While roller chain couplings can accommodate misalignment, they still provide torsional rigidity, ensuring efficient power transmission without significant losses.

By allowing for misalignment while maintaining reliable torque transmission, roller chain couplings are well-suited for various power transmission applications, including those where slight misalignment is unavoidable or expected.

editor by CX 2024-01-15

China Hot selling Double Row Roller Chain Shaft Coupling Sprocket Chain Rigid Coupling Kc5014 Kc5016

Product Description

Product Description

We are offering a wide range of Chain Coupling to our respected clients. Our offered products are used to join 2 pieces of rotating equipment while permitting the various degree of misalignment or end movement or both. Moreover, by careful installation and maintenance of couplings, substantial savings can be made in reduced downtime and maintenance costs.

Packaging & Shipping

Company Profile

FAQ

Retrofitting Roller Chain Couplings for Improved Performance

Yes, roller chain couplings can be retrofitted into existing systems to improve performance and enhance power transmission capabilities. Retrofitting is a cost-effective way to upgrade the coupling system without the need for significant modifications to the existing machinery.

When considering a retrofit with roller chain couplings, it is essential to ensure that the new couplings are compatible with the existing shaft sizes and operating conditions. The dimensions of the roller chain couplings should match the space available in the system, and the torque and speed ratings should meet or exceed the requirements of the application.

The advantages of retrofitting with roller chain couplings include:

- Increased Torque Capacity: Roller chain couplings can handle higher torque loads compared to some other coupling types, providing improved power transmission capabilities.

- Better Misalignment Tolerance: Roller chain couplings can accommodate both angular and parallel misalignments, reducing stress on the connected equipment and extending its service life.

- Shock Load Absorption: The flexibility of roller chain couplings allows them to absorb shock loads, protecting the drivetrain and other mechanical components from sudden impacts.

- Reduced Downtime: Retrofitting can be a quick and straightforward process, minimizing downtime during the upgrade.

Before proceeding with the retrofit, it is essential to consult with coupling manufacturers or engineering experts to ensure the proper selection and installation of roller chain couplings. Additionally, regular maintenance and inspections are crucial to ensure continued optimal performance and reliability of the retrofitted coupling system.

Maintenance Requirements for Roller Chain Couplings

To ensure the optimal performance and longevity of roller chain couplings, regular maintenance is essential. Here are some key maintenance requirements:

- Lubrication: Regularly lubricate the roller chain and sprockets to reduce friction and wear. Use the appropriate lubricant recommended by the coupling manufacturer.

- Inspections: Periodically inspect the coupling for signs of wear, misalignment, or damage. Look for elongation or wear of the roller chain, damaged sprocket teeth, or any signs of excessive vibration.

- Tightening: Check and ensure that all fasteners, such as bolts and set screws, are properly tightened to the manufacturer’s recommended torque specifications.

- Alignment: Maintain proper alignment between the driving and driven shafts to prevent undue stress on the coupling components.

- Cleanliness: Keep the coupling and surrounding area clean and free from debris or contaminants that could interfere with its operation.

- Temperature: Avoid operating the coupling beyond its recommended temperature limits, as excessive heat can lead to premature failure.

- Replacement: Replace any worn or damaged components promptly to prevent further damage to the coupling or connected equipment.

Regular maintenance not only ensures the coupling’s optimal performance but also helps identify potential issues early, allowing for timely repairs or replacements. It is crucial to follow the manufacturer’s maintenance guidelines and schedule to ensure the coupling’s reliability and prevent unexpected failures that could disrupt operations and lead to costly downtime.

Working Principle of Roller Chain Coupling and Its Advantages

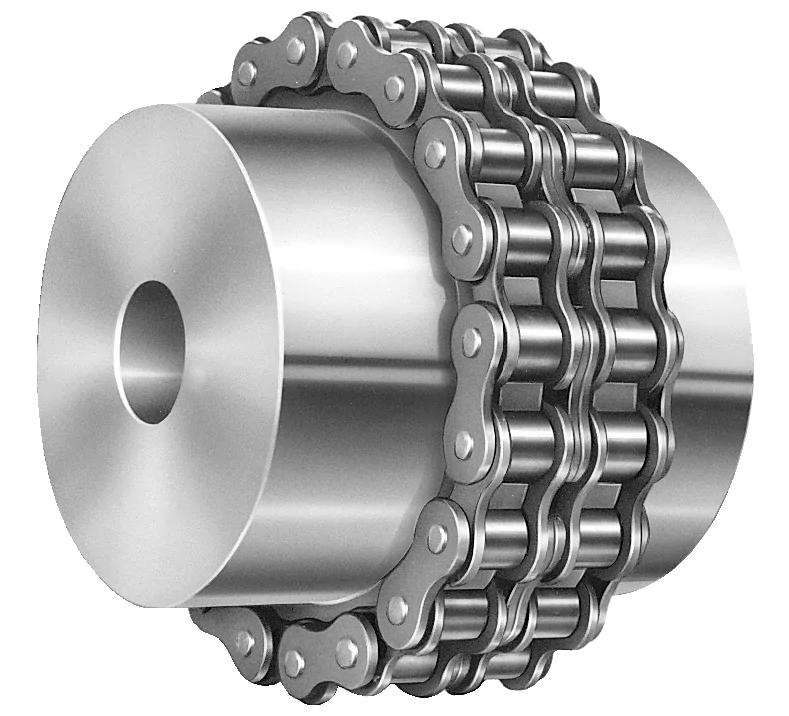

A roller chain coupling works on the principle of transferring torque between two shafts using a roller chain wrapped around sprockets on each shaft. The sprockets are connected by the roller chain, and when one sprocket rotates, it drives the other sprocket, transmitting the torque from one shaft to the other.

The advantages of roller chain couplings over other coupling types include:

- High Torque Capacity: Roller chain couplings can handle high torque loads, making them suitable for heavy-duty industrial applications.

- Compact Design: The compact and simple design of roller chain couplings allows for easy installation in tight spaces and restricted environments.

- Misalignment Tolerance: Roller chain couplings can accommodate angular, parallel, and axial misalignments between the shafts, reducing the need for precise alignment during installation.

- Shock Absorption: The inherent flexibility of the roller chain allows it to absorb shocks and dampen vibrations, protecting connected equipment from sudden loads and impacts.

- Cost-Effective: Roller chain couplings are generally cost-effective compared to other coupling types, providing an economical solution for power transmission needs.

- Wide Application Range: Roller chain couplings are used in various industries, including manufacturing, agriculture, construction, and material handling, due to their versatility and reliable performance.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain and require minimal lubrication to keep the chain running smoothly.

- Long Service Life: When properly installed and maintained, roller chain couplings offer a long service life, contributing to the overall efficiency and reliability of mechanical systems.

Overall, the working principle and advantages of roller chain couplings make them a popular choice for transmitting torque between shafts in diverse industrial applications.

editor by CX 2023-11-27

China high quality Double Row Roller Chain Shaft Coupling Sprocket Chain Rigid Coupling Kc5014 Kc5016

Product Description

Product Description

We are offering a wide range of Chain Coupling to our respected clients. Our offered products are used to join 2 pieces of rotating equipment while permitting the various degree of misalignment or end movement or both. Moreover, by careful installation and maintenance of couplings, substantial savings can be made in reduced downtime and maintenance costs.

Packaging & Shipping

Company Profile

FAQ

Comparison of Roller Chain Couplings to Other Coupling Types

Roller chain couplings offer distinct advantages and characteristics that set them apart from other coupling types, such as gear or disc couplings. Below is a comparison of roller chain couplings with these two commonly used coupling types:

- Roller Chain Couplings:

– Roller chain couplings are flexible and can accommodate misalignments, making them ideal for applications where shafts may not be perfectly aligned.

– They offer good shock absorption, which is beneficial in systems with varying loads or frequent starts and stops.

– Roller chain couplings are relatively compact and lightweight compared to other couplings, making them suitable for space-constrained installations.

– These couplings are cost-effective and provide a reliable and efficient power transmission solution.

- Gear Couplings:

– Gear couplings are capable of handling high torque and can transmit power efficiently, making them suitable for heavy-duty applications.

– They have a high level of torsional rigidity, ensuring accurate torque transmission without backlash.

– Gear couplings are generally more expensive than roller chain couplings.

– They require accurate alignment during installation, which can be challenging in some applications.

- Disc Couplings:

– Disc couplings offer high torque capacity and torsional stiffness, providing precise torque transmission and no backlash.

– They have a compact design and are often used in applications with limited space.

– Disc couplings can handle misalignment to some extent but may not be as forgiving as roller chain couplings.

– They are generally more expensive than roller chain couplings.

When choosing the appropriate coupling type, it is essential to consider the specific requirements of the application, such as torque, misalignment, speed, space limitations, and budget constraints. Each coupling type has its strengths, and the selection should be based on the demands of the mechanical power transmission system.

Materials Used in Manufacturing Roller Chain Couplings

Roller chain couplings are typically constructed from high-quality materials to ensure durability and reliable performance. The most common materials used in their manufacturing include:

- Steel: Steel is a popular choice for roller chain couplings due to its excellent strength and resistance to wear. It can handle high torque and speed requirements, making it suitable for a wide range of industrial applications.

- Stainless Steel: Stainless steel is used when corrosion resistance is required. It is often employed in industries where the coupling is exposed to moisture, chemicals, or harsh environmental conditions.

- Cast Iron: Cast iron is known for its robustness and excellent heat dissipation properties. It is commonly used in applications where shock absorption and reduced vibrations are essential.

- Aluminum: Aluminum is a lightweight material that offers good strength-to-weight ratio. It is commonly used in applications where reducing the overall weight of the system is critical.

- Nickel-Plated: Nickel-plated roller chain couplings provide enhanced corrosion resistance, making them suitable for applications in challenging environments.

When selecting a roller chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, environment, and potential exposure to corrosive substances. Choosing the right material ensures the coupling’s longevity and efficient power transmission in the intended operating conditions.

Key Design Considerations for Roller Chain Couplings in Power Transmission Systems

When using roller chain couplings in power transmission systems, several key design considerations should be taken into account:

- Torque and Power Ratings: Calculate the required torque and power ratings to ensure the roller chain coupling can handle the expected loads and prevent overloading.

- Speed: Consider the operating speed of the coupling to select a roller chain and sprocket combination that can handle the rotational speed without experiencing excessive wear or fatigue.

- Shaft Sizes: Ensure that the roller chain coupling’s sprockets are compatible with the shaft sizes of the connected equipment. Proper fit is crucial to transmit torque effectively and prevent slippage.

- Misalignment: Assess the potential misalignments between the shafts and choose a roller chain coupling that can accommodate the expected angular, parallel, and axial misalignments to reduce stress on the system.

- Service Environment: Consider the operating conditions, such as temperature, humidity, and exposure to contaminants, and select roller chain coupling materials that can withstand the environmental factors for extended service life.

- Lubrication: Determine the lubrication requirements of the roller chain coupling and establish a maintenance schedule to ensure proper lubrication and prevent premature wear.

- Space Limitations: Take into account any spatial restrictions or limitations in the installation area to select a roller chain coupling that fits within the available space.

- Alignment Maintenance: Plan for periodic alignment checks and adjustments to maintain the optimal performance of the roller chain coupling and extend its service life.

- Cost: Evaluate the budget constraints and compare the cost of different roller chain coupling options to choose the most cost-effective solution without compromising performance.

By considering these design factors, engineers can ensure that the roller chain coupling performs optimally and provides reliable power transmission in their specific power transmission systems.

editor by CX 2023-09-07

China Best Sales Kc Series Power Transmission Steel Casting Industrial Double Strand Flexible Shaft Sprocket Roller Chain Coupling

Product Description

Kc Series Power Transmission Steel casting Industrial Double Strand Flexible Shaft Sprocket Roller Chain Coupling

The chain coupling,compose of two-strand roller chains and 2 sprockets,features simple and compact structure,and high flexibility,power transmission capability and durability.What’s more,the chain coupling allows simple connection/disconnection,and the use of the housing enhances safety and durability.

Related products:

Production workshop:

Company information:

Comparison of Roller Chain Couplings to Other Coupling Types

Roller chain couplings offer distinct advantages and characteristics that set them apart from other coupling types, such as gear or disc couplings. Below is a comparison of roller chain couplings with these two commonly used coupling types:

- Roller Chain Couplings:

– Roller chain couplings are flexible and can accommodate misalignments, making them ideal for applications where shafts may not be perfectly aligned.

– They offer good shock absorption, which is beneficial in systems with varying loads or frequent starts and stops.

– Roller chain couplings are relatively compact and lightweight compared to other couplings, making them suitable for space-constrained installations.

– These couplings are cost-effective and provide a reliable and efficient power transmission solution.

- Gear Couplings:

– Gear couplings are capable of handling high torque and can transmit power efficiently, making them suitable for heavy-duty applications.

– They have a high level of torsional rigidity, ensuring accurate torque transmission without backlash.

– Gear couplings are generally more expensive than roller chain couplings.

– They require accurate alignment during installation, which can be challenging in some applications.

- Disc Couplings:

– Disc couplings offer high torque capacity and torsional stiffness, providing precise torque transmission and no backlash.

– They have a compact design and are often used in applications with limited space.

– Disc couplings can handle misalignment to some extent but may not be as forgiving as roller chain couplings.

– They are generally more expensive than roller chain couplings.

When choosing the appropriate coupling type, it is essential to consider the specific requirements of the application, such as torque, misalignment, speed, space limitations, and budget constraints. Each coupling type has its strengths, and the selection should be based on the demands of the mechanical power transmission system.

Reducing Vibrations and Ensuring Smooth Operation with Roller Chain Couplings

Roller chain couplings are designed to provide a flexible and torsionally soft connection between shafts, which helps in reducing vibrations and ensuring smooth operation in mechanical power transmission systems. Here’s how roller chain couplings contribute to achieving these benefits:

- Shock Absorption: Roller chain couplings have the ability to absorb and dampen shock loads that may occur due to sudden starts, stops, or changes in the load. This feature prevents the transmission of these shocks to connected equipment, reducing vibrations and protecting the system from mechanical damage.

- Torsional Flexibility: The flexibility of roller chain couplings allows for slight misalignments between shafts. This capability helps in accommodating minor misalignments, which might otherwise lead to increased vibrations and noise in rigid coupling systems.

- Uniform Load Distribution: Roller chain couplings distribute the transmitted torque uniformly along the chain, reducing stress concentration on specific components. This even distribution of load helps in maintaining smooth operation and prolonging the life of the coupling.

- Damping Properties: The material properties of roller chain couplings, such as the use of elastomeric or plastic elements in some designs, provide inherent damping characteristics. This damping helps in absorbing vibrations and preventing resonance, ensuring stable and smooth operation.

- Reduced Backlash: Roller chain couplings exhibit minimal backlash due to the precise fit of the chain’s teeth with the sprockets. This feature is beneficial in applications that require accurate positioning and motion control.

By reducing vibrations and ensuring smooth operation, roller chain couplings contribute to improved overall system performance, reduced wear and tear on components, and enhanced reliability in various industrial applications.

Accommodating Misalignment and Reliable Torque Transmission in Roller Chain Couplings

Roller chain couplings are designed to accommodate misalignment and provide reliable torque transmission in mechanical power transmission systems. They achieve this through the following features:

- Elongated Holes: The roller chain coupling’s hubs have elongated holes that allow for angular misalignment between the connected shafts. These holes provide flexibility and prevent excessive stress on the coupling and connected equipment.

- Roller Chain Design: The roller chain used in the coupling is a flexible and robust component that can transmit torque even in situations with slight misalignment. The design of the roller chain ensures smooth engagement and disengagement of the sprockets, reducing wear and power loss.

- Tension Adjustment: Roller chain couplings typically have an adjusting mechanism that allows for tensioning the chain. Proper tensioning is crucial for maintaining efficient torque transmission and preventing slippage.

- Single or Double Roller Chain: Some roller chain couplings come with a double roller chain design, which increases the torque capacity and allows for higher misalignment compensation.

- Torsionally Rigid Coupling: While roller chain couplings can accommodate misalignment, they still provide torsional rigidity, ensuring efficient power transmission without significant losses.

By allowing for misalignment while maintaining reliable torque transmission, roller chain couplings are well-suited for various power transmission applications, including those where slight misalignment is unavoidable or expected.

editor by CX 2023-08-17

China high quality Double Row Roller Chain Shaft Coupling Sprocket Chain Rigid Coupling Kc5014 Kc5016

Product Description

Product Description

We are offering a wide range of Chain Coupling to our respected clients. Our offered products are used to join 2 pieces of rotating equipment while permitting the various degree of misalignment or end movement or both. Moreover, by careful installation and maintenance of couplings, substantial savings can be made in reduced downtime and maintenance costs.

Packaging & Shipping

Company Profile

FAQ

Standard Sizes and Specifications of Roller Chain Couplings

Roller chain couplings come in various sizes and specifications to accommodate a wide range of mechanical power transmission applications. The standard sizes and specifications of roller chain couplings typically include:

- Chain Size: Roller chain couplings are available in different chain sizes, such as 40, 50, 60, 80, 100, etc. The chain size indicates the pitch of the roller chain used in the coupling.

- Torque Capacity: The torque capacity of a roller chain coupling varies based on its size and design. Manufacturers provide torque ratings that specify the maximum amount of torque the coupling can handle without failure.

- Speed Rating: Roller chain couplings have a maximum speed rating, which indicates the highest rotational speed at which the coupling can operate safely and efficiently.

- Material: Roller chain couplings are commonly made from materials such as carbon steel, stainless steel, or nickel-plated steel, providing different levels of strength, corrosion resistance, and durability.

- Hub Type: Roller chain couplings may come with different hub types, such as pilot bore hubs or taper bore hubs, to suit various shaft connections.

- Number of Teeth: Some roller chain couplings have specific tooth configurations that can affect their performance and backlash characteristics.

- Misalignment Capacity: Manufacturers specify the maximum allowable misalignment (angular and parallel) that the coupling can accommodate to ensure reliable operation.

It is essential to refer to the manufacturer’s catalogs or product specifications to determine the exact sizes and specifications available for specific roller chain couplings. Selecting the right size and specifications depends on the application’s requirements, including torque, speed, misalignment, and environmental conditions.

Materials Used in Manufacturing Roller Chain Couplings

Roller chain couplings are typically constructed from high-quality materials to ensure durability and reliable performance. The most common materials used in their manufacturing include:

- Steel: Steel is a popular choice for roller chain couplings due to its excellent strength and resistance to wear. It can handle high torque and speed requirements, making it suitable for a wide range of industrial applications.

- Stainless Steel: Stainless steel is used when corrosion resistance is required. It is often employed in industries where the coupling is exposed to moisture, chemicals, or harsh environmental conditions.

- Cast Iron: Cast iron is known for its robustness and excellent heat dissipation properties. It is commonly used in applications where shock absorption and reduced vibrations are essential.

- Aluminum: Aluminum is a lightweight material that offers good strength-to-weight ratio. It is commonly used in applications where reducing the overall weight of the system is critical.

- Nickel-Plated: Nickel-plated roller chain couplings provide enhanced corrosion resistance, making them suitable for applications in challenging environments.

When selecting a roller chain coupling, it is essential to consider the specific requirements of the application, including torque, speed, environment, and potential exposure to corrosive substances. Choosing the right material ensures the coupling’s longevity and efficient power transmission in the intended operating conditions.

Torque and Speed Limits for Different Roller Chain Coupling Designs

The torque and speed limits of roller chain couplings can vary depending on their specific designs and construction materials. Some common factors that influence these limits include:

- Coupling Size: Larger roller chain couplings generally have higher torque and speed ratings compared to smaller ones.

- Construction Material: Couplings made from high-strength materials, such as stainless steel or hardened steel, can handle higher torques and speeds than those made from standard steel or other materials.

- Number of Strands: Roller chain couplings with multiple strands of roller chain can handle higher torques compared to single-strand designs.

- Operating Environment: The operating environment, including ambient temperature, humidity, and presence of contaminants, can affect the torque and speed capabilities of the coupling.

It is crucial to consult the manufacturer’s specifications and guidelines for each roller chain coupling model to determine its specific torque and speed limits. Exceeding the recommended torque and speed ratings may lead to premature wear, reduced efficiency, or even catastrophic failure of the coupling and connected equipment.

When selecting a roller chain coupling, it is essential to consider the application’s torque and speed requirements and choose a coupling that comfortably operates within those parameters. If the application demands high torques or speeds, it may be necessary to opt for larger or more robust coupling designs or explore alternative coupling types that better suit the specific requirements.

editor by CX 2023-08-11

China china factory aluminum shaft coupler The double loop flexible encoder coupling coupling energy

Warranty: negotiation

Relevant Industries: Manufacturing Plant, Equipment Fix Outlets

Personalized assistance: OEM, ODM, OBM

Construction: The double loop

Versatile or Rigid: Flexible

Standard or Nonstandard: Standard

Substance: Aluminium

Item title: Encoder Coupling

Variety: Flexible Coupling Setscrew

Bore variety: Concluded Bore

Surface Treatment: Anodic Oxidation

MOQ: 1 Pcs

Merchandise Characteristics Features1、Specially designed for encoder2、Good versatility, not easy to break3、Elastomer is created of polyurethane, oil resistant and oxidation resistant4、With superb absorption deviation ability, often utilized in huge eccentricity / angular deviation instances Attributes

| Name | 8 Variety Encoder Coupling |

| Material | Main body:Aluminum alloy; Elastomer:Polyurethane |

| Surface treatment | Anodic oxidation |

| Customized provider | Support light customization and emblem customization |

| Remarks | The default engraving model identify and dimensions of the merchandise. If you require not engraving, you should get in touch with the client provider for feedback |

What Is a Coupling?

A coupling is a device used to connect two shafts. It transmits power between them and allows for some misalignment or end movement. There are several types of couplings. The most common ones are gear couplings and planetary couplings. However, there are many others as well.

Transfer of energy

Energy coupling is a process by which two biological reactions are linked by sharing energy. The energy released during one reaction can be used to drive the second. It is a very useful mechanism that synchronizes two biological systems. All cells have two types of reactions, exergonic and endergonic, and they are connected through energy coupling.

This process is important for a number of reasons. The first is that it allows the exchange of electrons and their energy. In a single molecule, this energy transfer involves the exchange of two electrons of different energy and spin. This exchange occurs because of the overlap interaction of two MOs.

Secondly, it is possible to achieve quadratic coupling. This is a phenomenon that occurs in circular membrane resonators when the system is statically deflected. This phenomenon has been gaining a great deal of interest as a mechanism for stronger coupling. If this mechanism is employed in a physical system, energy can be transferred on a nanometer scale.

The magnetic field is another important factor that affects the exchange of energy between semiconductor QWs. A strong magnetic field controls the strength of the coupling and the energy order of the exciton. The magnetic field can also influence the direction of polariton-mediated energy transfer. This mechanism is very promising for controlling the routing of excitation in a semiconductor.

Functions

Couplings play a variety of functions, including transferring power, compensating for misalignment, and absorbing shock. These functions depend on the type of shaft being coupled. There are four basic types: angular, parallel, and symmetrical. In many cases, coupling is necessary to accommodate misalignment.

Couplings are mechanical devices that join two rotating pieces of equipment. They are used to transfer power and allow for a small degree of end-to-end misalignment. This allows them to be used in many different applications, such as the transmission from the gearbox to the differential in an automobile. In addition, couplings can be used to transfer power to spindles.

Types

There are two main types of couplings: rigid and flexible. Rigid couplings are designed to prevent relative motion between the two shafts and are suitable for applications where precise alignment is required. However, high stresses in the case of significant misalignment can cause early failure of the coupling. Flexible couplings, on the other hand, allow for misalignment and allow for torque transmission.

A software application may exhibit different types of coupling. The first type involves the use of data. This means that one module may use data from another module for its operation. A good example of data coupling is the inheritance of an object. In a software application, one module can use another module’s data and parameters.

Another type of coupling is a rigid sleeve coupling. This type of coupling has a pipe with a bore that is finished to a specified tolerance. The pipe contains two threaded holes for transmitting torque. The sleeve is secured by a gib head key. This type of coupling may be used in applications where a couple of shafts are close together.

Other types of coupling include common and external. Common coupling occurs when two modules share global data and communication protocols. This type of coupling can lead to uncontrollable error propagation and unforeseen side effects when changes are made to the system. External coupling, on the other hand, involves two modules sharing an external device interface or communication protocol. Both types of coupling involve a shared code structure and depend on the external modules or hardware.

Mechanical couplings are essential in power transmission. They connect rotating shafts and can either be rigid or flexible, depending on the accuracy required. These couplings are used in pumps, compressors, motors, and generators to transmit power and torque. In addition to transferring power, couplings can also prevent torque overload.

Applications

Different coupling styles are ideal for different applications, and they have different characteristics that influence the coupling’s reliability during operation. These characteristics include stiffness, misalignment capability, ease of installation and maintenance, inherent balance, and speed capability. Selecting the right coupling style for a particular application is essential to minimize performance problems and maximize utility.

It is important to know the requirements for the coupling you choose before you start shopping. A proper selection process takes into account several design criteria, including torque and rpm, acoustic signals, and environmental factors. Once you’ve identified these parameters, you can select the best coupling for the job.

A gear coupling provides a mechanical connection between two rotating shafts. These couplings use gear mesh to transmit torque and power between two shafts. They’re typically used on large industrial machines, but they can also be used in smaller motion control systems. In smaller systems, a zero-backlash coupling design is ideal.

Another type of coupling is the flange coupling. These are easy to manufacture. Their design is similar to a sleeve coupling. But unlike a sleeve coupling, a flange coupling features a keyway on one side and two threaded holes on the other. These couplings are used in medium-duty industrial applications.

Besides being useful for power transmission, couplings can also prevent machine vibration. If vibration occurs in a machine, it can cause it to deviate from its predetermined position, or damage the motor. Couplings, however, help prevent this by absorbing the vibration and shock and preventing damage to expensive parts.

Couplings are heavily used in the industrial machinery and electrical industries. They provide the necessary rotation mechanism required by machinery and other equipment. Coupling suppliers can help customers find the right coupling for a specific application.

Criteria for selecting a coupling

When selecting a coupling for a specific application, there are a number of different factors to consider. These factors vary greatly, as do operating conditions, so selecting the best coupling for your system can be challenging. Some of these factors include horsepower, torque, and speed. You also need to consider the size of the shafts and the geometry of the equipment. Space restrictions and maintenance and installation requirements should also be taken into account. Other considerations can be specific to your system, such as the need for reversing.

First, determine what size coupling you need. The coupling’s size should be able to handle the torque required by the application. In addition, determine the interface connection, such as straight or tapered keyed shafts. Some couplings also feature integral flange connections.

During the specification process, be sure to specify which materials the coupling will be made of. This is important because the material will dictate most of its performance characteristics. Most couplings are made of stainless steel or aluminum, but you can also find ones made of Delrin, titanium, or other engineering-grade materials.

One of the most important factors to consider when selecting a coupling is its torque capability. If the torque rating is not adequate, the coupling can be damaged or break easily. Torque is a major factor in coupling selection, but it is often underestimated. In order to ensure maximum coupling performance, you should also take into consideration the size of the shafts and hubs.

In some cases, a coupling will need lubrication throughout its lifecycle. It may need to be lubricated every six months or even once a year. But there are couplings available that require no lubrication at all. An RBI flexible coupling by CZPT is one such example. Using a coupling of this kind can immediately cut down your total cost of ownership.

editor by czh 2023-02-23

Walk-Behind made in China – replacement parts – final drive chain vs shaft China in Al-Mukalla Yemen Double Drum Road Roller Compactor Gyrc-70 with ce certificate top quality low price

We – EPG Group the largest Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For far more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

Total use has been made of all types of sophisticated techniques and technological innovation to get to excelsior manufacturing. Our With EPG model registered in a lot more than 70 countries like The usa , Europe , Japan and so on, it has companions among planet prime enterprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, and so on.huge stock levels on zinc plated, strong metal shaft collars assure prompt pleasure of any dimension requirement. Unplated, black-oxide and stainless steel strong collars are commonly offered. Black-oxide metal clamp kind collars are likewise stocked for unbeatable support. Mounted bearing and linear bearing orders are regularly delivered inside 24 several hours and our change-close to time on lower-to-size linear shafting will exceed your expectations. ISO 9001:2000 qualified. Stocking distributor of electricity transmission products including roller & multiple strand roller chains. Items also contain brakes, push factors, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also offered. China manufacturing unit price Honda GX390 GYRC-70 Stroll-behind Double Drum Road Roller Compactor

Characteristics&colon

one&periodDeadman management lever offers reversing protection

two&periodMechanical parking brake

3&periodMulti placement handle for operator convenience and simplified transport

4&periodBuilt-in oil cooler will increase the productivity of ma Ergonomically created contro EPT are conveniently positioned to ensure pace&comma course&interval

5&periodAnti vibration controls ensure non-fatiguing and reduced HAV for the operator&period of time

six&periodSide and control clearance enable for a closet technique to pavement&comma wall&comma control and EPT obstacle

7&periodDual easy drums with beveled edge eliminates mark on the floor and asphalt&period

8&periodEasy access to entrance mounted Diesel motor&period

nine&period35 liters&comma corrosion-totally free drinking water tank mounted at the rear of roller minimizes seem and retains du EPT to a minimum&period of time

10&periodVibration is controlled by easy to attain on and off swap in speed managed hand lever&time period

11&periodTwo scraper bars on each and every drum ensure a clean drum when functioning on asphalt

twelve&periodMinimum overhand supplying suitable aspect and suppress clearance

13&periodErgonomically layout deal with with lifeless guy handle supplying safety to operator in reversing purposes&period

14&periodA fully hydraulic-drive system consists of hydraulic bump and hydraulic motors provide infinitely variable

fifteen&periodworking pace for journey and vibration&comma reducing typical maintenance and changes that chain driven rollers require&period

sixteen&periodUnique clutch&solpump generate system provides simple chilly climate starting and permits for no-load starting up of engine&period of time

Specification&colon

| Model | GYRC-70 |

| Motor Type | Honda GX390 |

| Electrical power kw&lparhp&rpar | 9&period6&lpar13&period0&rpar |

| Bodyweight kg&lparlbs&rpar | 740&lpar1628&rpar |

| Drum Diameter cm&lparin&rpar | sixty five&ast40&lpar25&ast15&period7&rpar |

| Centrifugal Drive kN | 24 |

| Frequency vpm&solhz | 3600&lpar61&rpar |

| Journey Velocity km&solhr | two&period5 |

| Drinking water tank Ability L | 35 |

EPT Operation PROCESSING

ASSEMBLING

Package deal

TRANSPORTATION

Efficiency

The use of original gear manufacturer’s (OEM) component numbers or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our organization and the detailed replacement parts contained herein are not sponsored, authorized, or produced by the OEM.

Large China 2004 silverado drive shaft Heavy Duty Metallic Double Flexible Diaphragm Coupling with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto factory in China with five diverse branches. For much more details: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

JM II J Sort Diaphragm Coupling With Intermediate Shaft

JM series diaphragm versatile coupling is extensively utilised in equipment and equipment industry, metallurgy, mines, petroleum, chemical, electrical power, shipbuilding, lifting transport, textile, mild industry, agricultural machinery, printing machinery and h2o pump, enthusiast, and so on. in the transmission of electricity equipment.

The main qualities of JM Sequence Diaphragm Coupling:

one.Payment two axis misalignment of the potential, and tooth kind coupling can be significantly far more than a double angle displacement, radial displacement of the small, versatile, enabling a certain axial, radial and angular displacement.

two. Obvious damping result, no sounds, no put on and tear.

three.High transmission efficiency, up to ninety nine.86%. Especially appropriate for medium and higher pace high electrical power transmission.

four.Adapt to higher temperature (-80+three hundred) and harsh atmosphere, and can be in shock, vibration, security and dynamic situations.

five.Straightforward composition, gentle excess weight, modest size, practical assembly and disassembly. Without shifting the machine can be disassembled (with intermediate type), no need to have of lubrication.

six.Properly convey the rotational speed, the operation has not turned bad, can be utilized for the transmission of precision equipment.

JMIIJ Sort Diaphragm Coupling Fundamental Parameter And Principal Dimension(JB/T 0571 seven-one 0571 )

| Kind | Nominal torque Tn |

Peak torque Tmax |

Max Speed nmax |

Bore Diameter d,d1 |

Bore duration | D | D1 | D2 | L1min | t | Mass | Rotary inertia |

|||

| Jone type | Y kind |

L (advise) |

L1min | Every single 1meter of mass extra | |||||||||||

| L | |||||||||||||||

| N·m | N·m | r·min-one | mm | kg | kg·mtwo | ||||||||||

| JMIIJ1 | sixty three | 100 | 0571 | 20,22,24 | 38 | 52 | forty | ninety two | 53 | forty five | 70 | 8±0.two | two | 4.one | .002 |

| 25,28 | 44 | sixty two | |||||||||||||

| 30,32,35,38 | 60 | eighty two | |||||||||||||

| JMIIJ2 | 100 | two hundred | 8400 | 25,28 | 44 | 62 | 45 | 102 | sixty three | eighty | two.nine | .003 | |||

| thirty,32,35,38 | 60 | eighty two | |||||||||||||

| 40,forty two,forty five | 84 | 112 | |||||||||||||

| JMIIJ3 | 250 | 400 | 6700 | thirty,32,35,38 | sixty | eighty two | fifty five | 128 | 77 | seventy six | 96 | 11±0.3 | 5.seven | eight | .009 |

| forty,42,forty five,48,fifty,55 | eighty four | 112 | |||||||||||||

| JMIIJ4 | 500 | 800 | 5900 | 35,38 | sixty | eighty two | sixty five | one hundred forty five | ninety one | 116 | 8.five | .017 | |||

| forty,forty two,forty five,48,fifty,55,fifty six | 84 | 112 | |||||||||||||

| sixty,sixty three,sixty five | 107 | 142 | |||||||||||||

| JMIIJ5 | 800 | 1250 | 0571 | 40,forty two,45,48,50,55,56 | eighty four | 112 | seventy five | 168 | 105 | 102 | 136 | 14±0.three | 12.five | 12 | .034 |

| 60,sixty three,sixty five,70,71,75 | 107 | 142 | |||||||||||||

| JMIIJ6 | 1250 | 2000 | 0571 | forty five,48,fifty,fifty five,fifty six | 84 | 112 | eighty | 180 | 112 | a hundred and forty | 15±0.four | 16.5 | .053 | ||

| sixty,sixty three,65,70,71,seventy five | 107 | 142 | |||||||||||||

| 80 | 132 | 172 | |||||||||||||

| JMIIJ7 | 2000 | 0571 | 4300 | 50,fifty five,fifty six | eighty four | 112 | 200 | 120 | 114 | 21 | 19 | .082 | |||

| sixty,63,65,70,seventy one,75 | 107 | 142 | |||||||||||||

| 80,85 | 132 | 172 | |||||||||||||

| JMIIJ8 | 2500 | 4000 | 4200 | fifty five,56 | eighty four | 112 | 205 | one hundred twenty | 20±0.4 | 23 | .092 | ||||

| 60,sixty three,sixty five,70,71,seventy five | 107 | 142 | |||||||||||||

| eighty,eighty five | 132 | 172 | |||||||||||||

| JMIIJ9 | 0571 | 5000 | 4000 | fifty five,56 | eighty four | 112 | ninety | 215 | 128 | 127 | a hundred and sixty | 20±0.4 | 27 | 21 | .117 |

| sixty,63,sixty five,70,71,seventy five | 107 | 142 | |||||||||||||

| 80,85,90 | 132 | 172 | |||||||||||||

| JMIIJ10 | 4000 | 6300 | 3650 | sixty,63,65,70,seventy one,seventy five | 107 | 142 | 100 | 235 | 132 | a hundred and seventy | 23±0.5 | 36 | .191 | ||

| eighty,eighty five,ninety,ninety five | 132 | 172 | |||||||||||||

| JMIIJ11 | 5000 | 8000 | 3400 | 60,63,65,70,seventy one,seventy five | 107 | 142 | 250 | one hundred forty five | one hundred forty | forty two | 26 | .252 | |||

| 80,82,90,ninety five | 132 | 172 | |||||||||||||

| 100 | 167 | 212 | |||||||||||||

| JMIIJ12 | 6300 | ten thousand | 3200 | sixty,63,sixty five,70,seventy one,seventy five | 107 | 142 | 110 | 270 | 155 | a hundred ninety | fifty | . 0571 | |||

| 80,eighty five,90,95 | 132 | 172 | |||||||||||||

| a hundred,one hundred ten | 167 | 212115 | |||||||||||||

| JMIIJ13 | 8000 | 12500 | 2850 | sixty five,70,seventy one,seventy five | 107 | 142 | one hundred fifteen | 300 | 162 | 165 | two hundred | 27±0.6 | sixty six | 47 | .56 |

| 80,85,90,95 | 132 | 172 | |||||||||||||

| 100,a hundred and ten | 167 | 212 | |||||||||||||

| JMIIJ14 | ten thousand | 16000 | 2700 | 70,71,seventy five | 107 | 142 | one hundred twenty five | 320 | 176 | 220 | seventy eight | .seventy five | |||

| 80,eighty five,ninety,95 | 132 | 172 | |||||||||||||

| one hundred,110,120,125 | 167 | 212 | |||||||||||||

| JMIIJ15 | 12500 | 20000 | 2450 | seventy five | 107 | 142 | one hundred forty | 0571 | 186 | 240 | 32±0.7 | a hundred and ten | 51 | one.26 | |

| eighty,85,90,ninety five | 132 | 172 | |||||||||||||

| a hundred,a hundred and ten,120,one hundred twenty five | 167 | 212 | |||||||||||||

| 130 | 202 | 252 | |||||||||||||

| JMIIJ16 | 16000 | 25000 | 2300 | eighty,eighty five,90,ninety five | 132 | 172 | 145 | 0571 | 203 | 219 | 250 | a hundred twenty five | 72 | 1.63 | |

| a hundred,a hundred and ten,120,125 | 167 | 212 | |||||||||||||

| 130,a hundred and forty | 202 | 252 | |||||||||||||

| JMIIJ17 | 20000 | 0571 00 | 2150 | 90,ninety five | 132 | 172 | 165 | four hundred | 230 | 290 | one hundred sixty | two.45 | |||

| a hundred,a hundred and ten,one hundred twenty,one hundred twenty five | 167 | 212 | |||||||||||||

| one hundred thirty,a hundred and forty,150 | 202 | 252 | |||||||||||||

| one hundred sixty | 242 | 302 | |||||||||||||

| JMIIJ18 | 25000 | 40000 | 1950 | one hundred,a hundred and ten,a hundred and twenty,125 | 167 | 212 | 175 | 440 | 245 | three hundred | 38±0.nine | 220 | 3.99 | ||

| one hundred thirty,a hundred and forty,one hundred fifty | 202 | 252 | |||||||||||||

| one hundred sixty,a hundred and seventy | 242 | 302 | |||||||||||||

| JMIIJ19 | 0571 00 | 50000 | 1850 | a hundred,one hundred ten,120,one hundred twenty five | 167 | 212 | 185 | 460 | 260 | 267 | 320 | 245 | 89 | four.ninety eight | |

| a hundred thirty,one hundred forty,a hundred and fifty | 202 | 252 | |||||||||||||

| one hundred sixty,one hundred seventy,a hundred and eighty | 242 | 302 | |||||||||||||

| JMIIJ20 | 0571 00 | 56000 | 1800 | one hundred twenty,125 | 167 | 212 | 200 | 480 | 280 | 267 | 0571 | 38±0.nine | 275 | 89 | six.28 |

| 130,140,one hundred fifty | 202 | 252 | |||||||||||||

| one hundred sixty,one hundred seventy,one hundred eighty | 242 | 302 | |||||||||||||

| 190,two hundred | 282 | 0571 | |||||||||||||

| JMIIJ21 | 40000 | 63000 | 1700 | a hundred and twenty,a hundred twenty five | 167 | 212 | 210 | five hundred | 295 | 0571 | 320 | seven.68 | |||

| 130,140,one hundred fifty | 202 | 252 | |||||||||||||

| 160,a hundred and seventy,180 | 242 | 302 | |||||||||||||

| 190,200 | 282 | 0571 | |||||||||||||

| JMIIJ22 | 50000 | 80000 | 1600 | a hundred and forty,150 | 202 | 252 | 220 | 450 | 0571 | 299 | 380 | 44±1 | four hundred | a hundred and ten | 11.six |

| one hundred sixty,one hundred seventy,one hundred eighty | 242 | 302 | |||||||||||||

| one hundred ninety,two hundred,220 | 282 | 0571 | |||||||||||||

| JMIIJ23 | 63000 | 100000 | 1450 | one hundred forty,150 | 202 | 252 | 240 | 600 | 0571 | 0571 | 410 | 50±1.two | 560 | 145 | 19.8 |

| 160,170,a hundred and eighty | 242 | 302 | |||||||||||||

| one hundred ninety,two hundred,220 | 282 | 0571 | |||||||||||||

| 240 | 330 | 410 | |||||||||||||

| JMIIJ24 | 80000 | 125000 | 1400 | a hundred and sixty,one hundred seventy,180 | 242 | 302 | 255 | 620 | 0571 | 440 | 620 | 23.six | |||

| a hundred ninety,200,220 | 282 | 0571 | |||||||||||||

| 240,250 | 330 | 410 | |||||||||||||

| JMIIJ25 | 90000 | 140000 | 1300 | a hundred and eighty | 242 | 302 | 275 | 0571 | 385 | 480 | 740 | 31.nine | |||

| one hundred ninety,200,220 | 282 | 0571 | |||||||||||||

| 240,250,260 | 330 | 410 | |||||||||||||

| 280,three hundred | 380 | 0571 | |||||||||||||

| JMIIJ26 | 12000 | 180000 | 1200 | one hundred ninety,200,220 | 282 | 0571 | 295 | 720 | 410 | 406 | 0571 | 60±1.4 | 0571 | 190 | fifty.four |

| 240,250,260 | 330 | 410 | |||||||||||||

| 280,300 | 380 | 0571 | |||||||||||||

| JMIIJ27 | 140000 | 200000 | 1150 | 220 | 282 | 0571 | three hundred | 740 | 420 | 520 | 1050 | fifty seven | |||

| 240,250,260 | 330 | 410 | |||||||||||||

| 280,three hundred | 380 | 0571 | |||||||||||||

| JMIIJ28 | 160000 | 224000 | 1100 | 240,250,260 | 330 | 410 | 320 | 0571 | 450 | 0571 | 560 | 1200 | 215 | 69.four | |

| 280,300 | 380 | 0571 | |||||||||||||

| JMIIJ29 | 180000 | 280000 | 1050 | 250,260 | 330 | 410 | 0571 | 820 | 490 | 600 | 1400 | ninety five.five | |||

| 280,three hundred,320 | 380 | 0571 | |||||||||||||

| 340 | 450 | 0571 | |||||||||||||

| JMIIJ30 | 280000 | 450000 | one thousand | 280,300,320 | 380 | 0571 | 0571 | 0571 | 480 | 0571 | 620 | 50±1.six | 1400 | 235 | 96.5 |

| 340,360 | 450 | 0571 | 0571 | 109.five | |||||||||||

| JMIIJ31 | 400000 | 630000 | 0571 | 300,320 | 380 | 0571 | 0571 | 520 | 610 | 630 | 60±1. | 1800 | 290 | 142 | |

| 340,360,380 | 450 | 0571 | 560 | 152 | |||||||||||

| 400 | 540 | 650 | 600 | 162 | |||||||||||

| JMIIJ32 | 450000 | 0571 000 | 880 | 320 | 380 | 0571 | 380 | 1030 | 480 | 622 | 690 | 2250 | 330 | 194 | |

| 340,360,380 | 450 | 0571 | 600 | 224 | |||||||||||

| four hundred,420 | 540 | 650 | 640 | 240 | |||||||||||

| JMIIJ33 | 560000 | 900000 | 820 | 360,380 | 450 | 0571 | 400 | 1080 | 0571 | 0571 | 726 | 66±2.2 | two 0571 | 390 | 271 |

| four hundred,420,440,450,460 | 540 | 650 | seven-hundred | 325 | |||||||||||

| JMIIJ34 | 1000000 | 1600000 | 740 | four hundred,420,440,450 | 540 | 650 | 460 | 1160 | 620 | 0571 | 0571 | 70±2.3 | 0571 | 450 | 387 |

| one hundred sixty,480,500 | 540 | 650 | 0571 | 465 | |||||||||||

| JMIIJ35 | 1400000 | 2240000 | 680 | 400,420,440,450,480,five hundred | 540 | 650 | 520 | 1290 | 0571 | 820 | 946 | 10±2.6 | 5000 | 0571 | 0571 |

| 530,560 | 680 | 800 | 840 | 810 | |||||||||||

| JMIIJ36 | 2000000 | 0571 0000 | 620 | 480,500 | 540 | 650 | 0571 | 1410 | 0571 | 900 | 1040 | 92±2.8 | 0571 | 0571 | 1050 |

| 530,560,600 | 680 | 800 | 920 | 1290 | |||||||||||

| JMIIJ37 | 2800000 | 4000000 | 0571 | 450,460,480,500 | 540 | 650 | 610 | 1530 | 810 | one thousand | 1100 | 105±3 | 8400 | 880 | 1630 |

| 530,560,600 | 680 | 800 | 980 | 1950 | |||||||||||

| JMIIJ38 | 4000000 | 6000000 | 520 | 560,600,630 | 680 | 800 | 670 | 1670 | 950 | 1100 | 1210 | 115±3.four | 11000 | 1050 | 2670 |

| 670, 0571 | 780 | – | 1070 | 3030 | |||||||||||

| JMIIJ39 | 5000000 | 8000000 | 480 | 600,630 | 680 | 800 | 0571 | one 0571 | 0571 | 1200 | 1320 | 125±3.7 | 14500 | one 0571 | 4060 |

| 670, 0571 , 0571 | 780 | – | 1170 | 4800 | |||||||||||

| JMIIJ40 | 6300000 | 10000000 | 430 | 670, 0571 , 0571 | 780 | 800 | 2000 | 1140 | 1300 | 1450 | 130±4 | 19000 | 1600 | 0571 | |

| 800,850 | 880 | 1290 | 0571 | ||||||||||||

| JMIIJ41 | 8000000 | 12500000 | four hundred | 0571 | 780 | 2200 | 1260 | 1400 | 1600 | 140±4.4 | 2500 | 1850 | 10400 | ||

| 800,850 | 880 | 1420 | 11900 | ||||||||||||

| JMIIJ42 | 10000000 | 16000000 | 0571 | 800,850 | 880 | 960 | 2400 | 1 0571 | 1500 | 1 0571 | 32000 | 2100 | 15200 | ||

| 900,950 | 980 | 1 0571 | 17400 | ||||||||||||

Manufacturing Pictures

♦Other Merchandise Checklist

| Transmission Machinery Areas Title |

Product |

| Universal Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| High Flexible Coupling | LM |

| Chain Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

♦Our Organization

Our organization provides various varieties of items. Large quality and realistic cost. We adhere to the theory of “quality very first, service initial, ongoing advancement and innovation to satisfy the clients” for the management and “zero defect, zero grievances” as the high quality objective. To EPT our services, we provide the goods with good good quality at the affordable price tag.

Welcome to customize items from our factory and please supply your design drawings or get in touch with us if you need other needs.

♦Our Solutions

one.Design and style Companies

Our design and style group has encounter in cardan shaft relating to merchandise design and style and development. If you have any requirements for your new solution or would like to make even more advancements, we are below to provide our help.

2.Merchandise Services

raw materia EPT → Reducing → Forging →Rough machining →Shot blasting →Heat treatment method →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3.Samples Treatment

We could produce the sample according to your requirement and amend the sample continuously to meet your require.

4.Investigation & Development

We generally research the new needs of the market and create the new design when there is new cars in the market.

five.Top quality Handle

Each and every step must be EPT take a look at by Specialist Employees according to the common of ISO9001 and TS16949.

♦FAQ

Q 1: Are you buying and selling company or company?

A: We are a expert company specializing in manufacturing

various sequence of couplings.

Q 2:Can you do OEM?

Indeed, we can. We can do OEM & ODM for all the customers with personalized artworks of PDF or AI format.

Q 3:How lengthy is your supply time?

Usually it is twenty-thirty times if the items are not in inventory. It is according to quantity.

Q 4: Do you offer samples ? Is it totally free or extra ?

Sure, we could supply the sample but not for totally free.Truly we have a very good price basic principle, when you make the bulk order then cost of sample will be deducted.

Q 5: How lengthy is your guarantee?

A: Our Warranty is twelve thirty day period below regular circumstance.

Q 6: What is the MOQ?

A:Generally our MOQ is 1pcs.

Q 7: Do you have inspection processes for coupling ?

A:one hundred% self-inspection prior to packing.

Q 8: Can I have a go to to your manufacturing facility prior to the get?

A: Positive,welcome to go to our manufacturing unit.

Q nine: What is actually your payment?

A:one) T/T. 2) L/C

♦Speak to Us

Net:

Incorporate: No.one EPT Street,Chengnan park,HangZhou Metropolis,ZheJiang Province,China

Pump China double yoke pto shaft Over-Gear Km71024 for Pto Drive Hydraulic System with ce certificate top quality low price

We – EPG Group the biggest agricultural gearbox and pto manufacturing facility in China with 5 different branches. For much more particulars: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

used driveshafts for sale pto yoke pins Our pto drive hydraulic pump merchandise pto shaft fix is bypy pto shafts well-known jeep cherokee xj front push shaft exported bush hog pto shaft for sale to 540 pto shaft extender the 6 spline pto shaft extension United tractor pto shaft for sale States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, much more than 60 nations around the world and regions.

Pump Above-Equipment KM71571 for PTO push hydraulic method

The Gearboxes are made for connecting gear pumps to farm tractor power take offs (PTO).Output speed of power get offs is 540rpm which can be in contrast with the appropriate operating speeds of hydraulic pumps.Diverse enter managing speeds can also be ideal,offered that the PTO gearbox output pace does not exceed 3000 rpm.

Gears

Manufactured in Steel UNI eighteen PCR M03.Stub teeth guarantee really substantial resistance and run extremely quietly.

Shafts

Produced in metal UNI sixteen CRN4.They are coupled with splined gears and are developed to stand the torque values mentioned in the catalogue.

Lubrication

SAE 90 equipment oil have to be place in the pto gearbox prior to use, alter the oil soon after the very first 60-80 hrs and then every 12 months or 1500 several hours which at any time fal EPT initial.

Upkeep

Remember to examine the oil stage by means of the EPT oil window every 50 hours.Working temperatures should not exceed 120 levels celcius underneath continuos obligation cycle.

Packaging & Shipping

Plastic bag packing for one particular piece / two parts in one exporting carton / 100 cartons put on a pallet

FAQ

1.Q:Is your company a trading business or a manufacturer?

A:Our organization is a trading firm also a manufacturer, we have our personal factory to create gearbox, pump support..And many others

Also we distribute gear pumps, tractor machinery,dump truck pump from selected quality suppliers to fulfill customers’ variable desire.

two.Q:What about the good quality handle and guarantee ?

A:”Top quality first, Clients foremost”.Each piece of goods is cheeked and tested strictly one by a single before packing and delivery.

Our items have one 12 months warranty, technical assist is countless from us.

three.Q:Can you offer samples for checking and screening?

A:Of course,we offer totally free samples for examining the create quality and real functionality of our goods,the freight need to have to be coverd by consumer.

four.Q:How can I get to your business?

A:Our business address is No.888 Huaxu Highway,Xihu (West Lake) Dis. district,ZheJiang ,China

It is about thirty minutes by vehicle from ZheJiang Xihu (West Lake) Dis.ao airport or ZheJiang Xihu (West Lake) Dis.ao Railway station.