Product Description

Introduction

- Oldham couplings are a 3 piece design comprised of 2 aluminum hubs press fit CZPT a center disk. Torque transmission is accomplished by mating the slots on the center disk to the drive tenons on the hubs. During operation the center disk slides on the tenons of each hub (which are orientated 90 apart) to transmit torque.

- While the couplings accommodate a small amount of angular and axial misalignment, they are especially useful in applications with parallel misalignment.

- We offers oldham couplings in set screw or clamp styles with bores ranging from 4mm to 35mm. Inch and metric hubs (set screw, clamp style, keyed, or keyless) are interchangeable and can be combined into a single coupling as long as they have the same outside diameter. Oldham coupling hubs are standard in black anodized aluminum for improved lubricity, increased life, and low inertia. Hubs are also available in stainless steel CZPT request for increased corrosion resistance.

Application

- Ideal for many light duty industrial and motion control applications, oldham couplings have the ability to protect more expensive machinery components.

- For example the oldham coupling acts as a torque limiter during overload. When the disk fails, it breaks cleanly and does not allow any transmission of power.

- Oldham couplings also have the advantage of electrical isolation due to the non-conductive nature of the center disk.

- This prevents electrical currents from being passed to delicate instruments which can cause inaccurate data readings or damage.

Feature

- High absorption capacity of radial misaligment

- They do not produce kinematic errors in transmission

- Elimination of loads on shaft

- Mechanical protection against excessive torque

- Replaceable disc

1. We have first-class testing equipment to detect linear guide various data parameters and control the quality of the linear guide.Whenever linear guides must first detected whether the quality is qualified and the unqualified linear guide will be eliminated directly.So we can get the trust of a large customer, and supply them for several years.

2. We have our own R & D capabilities, to help customers solve the problem of non-standard linear guides.We can also according to customer requirements change their own mark.

3. Price, our manufacture ensure that our prices across China are quite competitive.It is better for you to compare prices and quality among suppliers.But everyone knows you can not buy the highest quality products with the lowest price,but our product is the best quailty if you use equal price.

FAQ:

1. When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

2. How can I get a sample to check your quality ?

After price confirmed,sample order is available to check our quality.

3. What is your main products ?

Linear motion systems,like lead screws, flexible coupling,Miniature linear guide rails,ball screws,linear rod shaft,ceramic bearings …etc. But also CNC machining centers and CNC machinable tooling boards.

4. Could you get a better price on your products ?

Yes,you can.We will give the best price on all of the products you need,which can help you to compete other companies in your markets.

5. What is the strength of your company ?

We have a engineer team,who have well experienced on product’s and machine designs.We can help you to solve the problems you meet.

Welcome to inquiry US!

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 10-32 |

| Torque: | 30-50N.M |

| Bore Diameter: | 14mm |

| Structure: | Rigid and Flexible |

| Material: | Aluminum |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

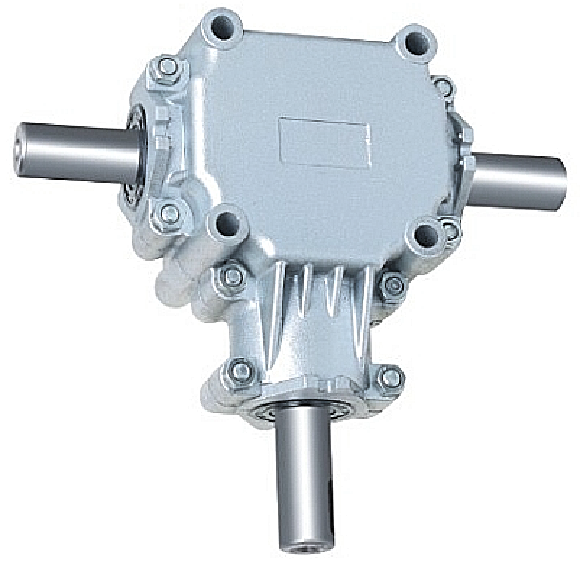

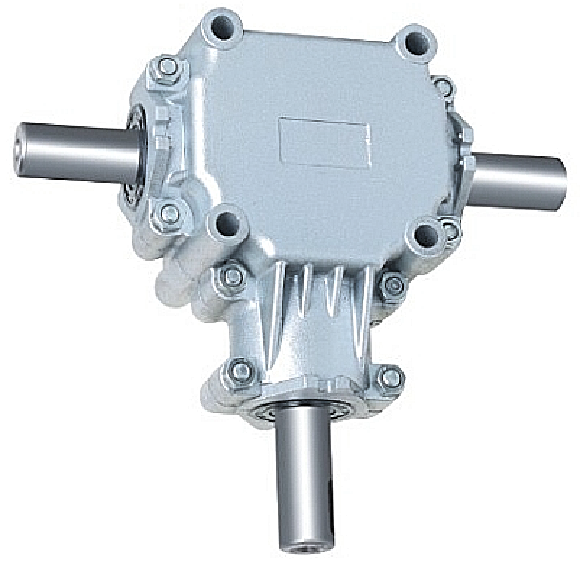

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as “sliced” couplings while others are known as “slit” couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don’t require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by CX 2023-05-19

China Zs Factory Price High Precision Flexible Coupling Single Disk Type for Automation Machinery edc coupling

Merchandise Description

Introduction

- Oldham couplings are a 3 piece layout comprised of 2 aluminum hubs press match CZPT a centre disk. Torque transmission is completed by mating the slots on the centre disk to the push tenons on the hubs. Throughout procedure the heart disk slides on the tenons of every hub (which are orientated ninety apart) to transmit torque.

- Whilst the couplings accommodate a small quantity of angular and axial misalignment, they are specifically useful in apps with parallel misalignment.

- We delivers oldham couplings in established screw or clamp designs with bores ranging from 4mm to 35mm. Inch and metric hubs (established screw, clamp type, keyed, or keyless) are interchangeable and can be blended into a one coupling as lengthy as they have the identical outdoors diameter. Oldham coupling hubs are normal in black anodized aluminum for improved lubricity, enhanced lifestyle, and minimal inertia. Hubs are also available in stainless metal CZPT ask for for improved corrosion resistance.

Software

- Ideal for several gentle responsibility industrial and motion handle applications, oldham couplings have the ability to defend a lot more expensive machinery components.

- For case in point the oldham coupling acts as a torque limiter in the course of overload. When the disk fails, it breaks cleanly and does not let any transmission of electricity.

- Oldham couplings also have the edge of electrical isolation owing to the non-conductive character of the centre disk.

- This helps prevent electrical currents from being handed to fragile devices which can trigger inaccurate data readings or hurt.

Attribute

- Higher absorption capacity of radial misaligment

- They do not generate kinematic glitches in transmission

- Elimination of masses on shaft

- Mechanical security against excessive torque

- Replaceable disc

one. We have very first-class screening products to detect linear guide various info parameters and control the high quality of the linear manual.Whenever linear guides need to very first detected whether the quality is competent and the unqualified linear guide will be eliminated immediately.So we can get the believe in of a big client, and source them for numerous years.

two. We have our possess R & D capabilities, to help consumers fix the dilemma of non-standard linear guides.We can also according to buyer requirements change their own mark.

3. Price, our manufacture ensure that our prices throughout China are quite aggressive.It is much better for you to evaluate prices and quality among suppliers.But everybody is aware you can not purchase the highest top quality items with the lowest price tag,but our product is the ideal quailty if you use equivalent value.

FAQ:

1. When can I get the quotation ?

We typically estimate inside of 24 hours after we get your inquiry. If you are very urgent to get the cost,you should phone us or tell us in your email so that we will regard your inquiry precedence.

two. How can I get a sample to verify your high quality ?

After price confirmed,sample get is obtainable to verify our good quality.

3. What is your primary goods ?

Linear motion methods,like direct screws, flexible coupling,Miniature linear manual rails,ball screws,linear rod shaft,ceramic bearings …and so forth. But also CNC machining facilities and CNC machinable tooling boards.

four. Could you get a better price tag on your merchandise ?

Indeed,you can.We will give the greatest price tag on all of the merchandise you want,which can help you to contend other businesses in your markets.

five. What is the energy of your firm ?

We have a engineer crew,who have properly experienced on product’s and device designs.We can help you to fix the troubles you meet up with.

Welcome to inquiry US!

|

/ Set | |

5 Sets (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 10-32 |

| Torque: | 30-50N.M |

| Bore Diameter: | 14mm |

| Structure: | Rigid and Flexible |

| Material: | Aluminum |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

|

/ Set | |

5 Sets (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 10-32 |

| Torque: | 30-50N.M |

| Bore Diameter: | 14mm |

| Structure: | Rigid and Flexible |

| Material: | Aluminum |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

Types of Couplings

A coupling is a device that connects two shafts together. It transmits power from one end to another and is used for joining rotating equipment. A coupling is flexible and can accommodate a certain amount of end movement and misalignment. This allows for more flexibility in applications. Various types of couplings are available, and each one serves a specific purpose.

Shaft couplings

There are many types of shaft couplings, and they are used in a wide range of applications. The type you need depends on the torque, speed, and horsepower you need, as well as the size of the shaft and its spatial limitations. You may also need to consider whether the coupling will accommodate misalignment.

Some shaft couplings are flexible, while others are rigid. Flexible couplings can accommodate up to two degrees of misalignment. They are available in different materials, including aluminum, stainless steel, and titanium. They can also be known by different names, depending on the industry. Some couplings can also be used in a single or multiple-shaft application.

The first type of shaft coupling is a rigid coupling, which consists of two parts that fit together tightly around the shafts. These couplings are designed to have more flexibility than sleeved models, and they can be used on fixed shafts as well. The flanged coupling, on the other hand, is designed for heavy loads and is made of two perpendicular flanges. The flanges are large enough to accommodate screws and are generally used with heavy-duty applications.

CZPT shaft couplings are a great choice if you’re looking for a shaft coupling that delivers high performance, durability, and low cost. These metal disc-style couplings provide low backlash and high torsional stiffness. Their high misalignment tolerance reduces reaction loads on connected components, which makes them ideal for high-speed precision applications. Available in single and double-disc models, they have torque ratings of up to 2,200 in-lbs. (250N) and are available in fourteen sizes.

When using shaft couplings, it is important to choose the right type for your application. Backlash can cause a shaft coupling to break or become unusable. In order to prevent this from happening, you should replace worn or loose parts, and ensure that the hub and key are evenly positioned with the shaft. If you’re using a shaft coupling in a motion-control system, it is important to keep the torque level consistent.

Flexible couplings

Flexible couplings are a type of coupling used to connect two shafts. They are made of rubber or plastic and allow for axial movement of the connected equipment. They do not require lubrication and are resistant to fatigue failure. Flexible couplings are useful for a number of applications. A common type of flexible coupling is the gear coupling, which has gear teeth inside its sleeve. Another type of flexible coupling is the metallic membrane coupling. A metallic membrane coupling is flexible due to flexing metallic discs.

One major disadvantage of flexible couplings is their inability to fit certain types of pipe. This is because most couplings need to be stretched to fit the pipe. This problem is often the result of a change in pipe technology. Traditionally, drain and soil pipe is made of ductile iron or cast iron. Today, most pipes are made of PVC, which has a larger outside diameter than either cast or ductile iron. Because of these changes in pipe technology, many coupling manufacturers have not updated their mold sizing.

Flexible couplings can be either metallic, elastomeric, or a combination of the three. While there are some common characteristics of each type, you should always consider the tradeoffs of each type before choosing one. Generally, the most important considerations when selecting a flexible coupling are torque, misalignment, and ease of assembly and maintenance.

Flexible couplings are used in a wide range of industries. They are useful for connecting two pipes to ensure torque transfer. Although the types available are different, these are the most adaptable couplings in the market. They can withstand movement, vibration, and bending without causing any damage to the piping.

Clutch couplings

A clutch coupling connects two rotating shafts by friction. The clutch engages power when the engine is running, disengaging power when the brake is applied. Clutch couplings are used in applications where the speed of a machine is variable or where continuous service is required. The clutch can transmit power, torque, and axial force.

Clutch couplings come in a variety of styles and configurations. Some couplings are flexible, while others are rigid. Flexible couplings are available in a variety of materials, including stainless steel and aluminum. Some couplings also have a non-backlash design, which helps compensate for misalignment.

Clutch couplings may be synchronous or asynchronous. Synchronous couplings engage and disengage automatically when the driven machine exceeds its output speed. These couplings are synchronized by a synchronizing mechanism. When the output speed is exceeded, the synchronizing mechanism initiates the engagement process. The synchronizing mechanism does not engage or disengage when the output speed drops.

High speed clutches are available from a variety of manufacturers. Some manufacturers offer OEM assembly, repair services, and third-party logistics. These manufacturers serve the automotive, chemical, food, and wood industries, as well as the oilfield and material handling industries. Custom clutches can be manufactured for specific applications and can be fitted with additional features, such as precision machined teeth or keyway slots and grooves.

Couplings are available in PCE, C/T, and metric bores. Typically, the size of the input and output shafts will determine which type of coupling is needed. In addition, clutches may be configured for intermediate or high speeds, depending on the required torque.

Clamped couplings

Clamped couplings are commonly used in a variety of industries. They can be used in medical equipment, dental equipment, military equipment, laboratory equipment, and in precision industrial controls. They are available in a wide variety of sizes and keyways. This type of coupling offers a number of advantages, including ease of installation and quick and easy replacement.

A clamp coupling connects two parts by compressing them together. The clamping elements can be formed in a variety of ways, but they all have a gap between their surfaces. This friction squeezes the two parts together, much like pulling two rubber gloves apart. This type of coupling is also useful for joining two hoses or piping units.

Clamped couplings are designed with a single or double clamping shaft. The clamping parts are mounted in two halves and are held together by eight socket head cap screws. They offer high torque capacity and require little installation space. Their high rigidity ensures good positioning accuracy, making them ideal for dynamic drives. In addition, they are wear-free and offer simple radial assembly.

The invention relates to a method and system for clamping pipes to a tank vessel. This invention also relates to a method of loading and unloading tank vessels. The method can be used in oil production platforms and other platforms. A single point mooring method is also used in oil production platforms.

Clamped couplings can also be flexible. They can join two shafts together while allowing a small amount of end movement and misalignment. These couplings may also be used in the assembly of motors and gearboxes.

CZPT’s coupling

CZPT couplings are designed to be flexible, allowing them to accommodate misaligned shafts and transmit torque in either direction. They are made with three discs, two hubs, and a center that are arranged with grooves and fins. These features allow for two degrees of freedom during assembly, and can accommodate misalignment of up to 5% of the shaft diameter.

CZPT couplings have many uses. For example, they can be used to join two parallel coaxial rotating shafts. Their ability to transmit torque at the same rotation mechanism and speed makes them ideal for applications where electrical currents may be a problem. Because the couplings are not made of metal, they are electrically isolated. Designers should test their couplings during the prototype stage to ensure they are working properly.

The CZPT coupling consists of two hubs with one slot on each. An intermediate disk is located between the two hubs. The discs are used to reduce or prevent wear on other machine parts. CZPT couplings are inexpensive and easy to replace. They also have electrical insulation, which makes them easy to repair or replace.

CZPT couplings are a popular choice for stepper motor-driven positioning stages. The plastic center disc offers electrical isolation and absorbs shocks from frequent start/stops. These couplings are available in through-hub and blind-bore styles and can be installed in many applications.

CZPT couplings also allow for small degrees of shaft misalignment. This allows them to function in systems where shaft access is limited. They are easily removed without tools.

editor by CX 2023-03-27

China Zs Factory Price High Precision Flexible Coupling Single Disk Type for Automation Machinery coupling constant

Product Description

Introduction

- Oldham couplings are a 3 piece style comprised of 2 aluminum hubs press suit CZPT a centre disk. Torque transmission is attained by mating the slots on the center disk to the push tenons on the hubs. For the duration of procedure the centre disk slides on the tenons of every single hub (which are orientated 90 apart) to transmit torque.

- Although the couplings accommodate a small volume of angular and axial misalignment, they are particularly valuable in programs with parallel misalignment.

- We provides oldham couplings in set screw or clamp variations with bores ranging from 4mm to 35mm. Inch and metric hubs (set screw, clamp type, keyed, or keyless) are interchangeable and can be blended into a single coupling as long as they have the exact same outside the house diameter. Oldham coupling hubs are normal in black anodized aluminum for enhanced lubricity, increased daily life, and reduced inertia. Hubs are also available in stainless metal CZPT for increased corrosion resistance.

Software

- Best for several gentle responsibility industrial and movement management purposes, oldham couplings have the capacity to shield much more expensive machinery components.

- For case in point the oldham coupling functions as a torque limiter in the course of overload. When the disk fails, it breaks cleanly and does not enable any transmission of power.

- Oldham couplings also have the edge of electrical isolation due to the non-conductive character of the middle disk.

- This stops electrical currents from becoming handed to fragile devices which can lead to inaccurate info readings or harm.

Characteristic

- High absorption capability of radial misaligment

- They do not produce kinematic problems in transmission

- Elimination of masses on shaft

- Mechanical defense towards too much torque

- Replaceable disc

one. We have very first-class screening equipment to detect linear guide various knowledge parameters and manage the high quality of the linear guide.Whenever linear guides should initial detected whether or not the quality is certified and the unqualified linear guide will be eradicated directly.So we can get the believe in of a large customer, and supply them for several several years.

two. We have our personal R & D capabilities, to help buyers fix the difficulty of non-standard linear guides.We can also according to customer requirements change their possess mark.

3. Price, our manufacture ensure that our rates across China are very aggressive.It is far better for you to assess charges and quality among suppliers.But everyone understands you can not get the highest top quality items with the most affordable value,but our item is the very best quailty if you use equal cost.

FAQ:

1. When can I get the quotation ?

We usually quotation within 24 hrs after we get your inquiry. If you are extremely urgent to get the value,you should phone us or explain to us in your email so that we will regard your inquiry priority.

two. How can I get a sample to check out your quality ?

Following price tag verified,sample get is offered to verify our quality.

3. What is your primary items ?

Linear movement techniques,like direct screws, versatile coupling,Miniature linear CZPT rails,ball screws,linear rod shaft,ceramic bearings …and so on. But also CNC machining facilities and CNC machinable tooling boards.

4. Could you get a much better price on your products ?

Indeed,you can.We will give the ideal value on all of the merchandise you need,which can help you to compete other firms in your markets.

5. What is the power of your business ?

We have a engineer crew,who have effectively seasoned on product’s and device styles.We can assist you to fix the troubles you meet up with.

Welcome to inquiry US!

|

US $1-15 / Set | |

5 Sets (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 10-32 |

| Torque: | 30-50N.M |

| Bore Diameter: | 14mm |

| Structure: | Rigid and Flexible |

| Material: | Aluminum |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $1-15 / Set | |

5 Sets (Min. Order) |

###

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 10-32 |

| Torque: | 30-50N.M |

| Bore Diameter: | 14mm |

| Structure: | Rigid and Flexible |

| Material: | Aluminum |

###

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

Types of Couplings

A coupling is a device that connects two shafts and transmits power from one to the other. Its main purpose is to join two pieces of rotating equipment. It also allows for some degree of misalignment or end movement. Here are a few examples of coupling types: Beam coupling, Flexible coupling, Magnetic coupling, and Shaft coupling.

Beam coupling

Beam couplings are used to couple motors and other devices. They are available in several types, including flexible, slit, and rigid beam couplings. Each has unique properties and characteristics. These couplings are best for applications requiring a high level of precision and long life. They are also a practical solution for the connection of stepping and servo motors with screw rods.

Beam couplings are usually made of stainless steel or aluminum alloy, and feature spiral and parallel cut designs. Multiple cuts allow the coupling to accommodate multiple beams and improve angular and parallel misalignment tolerances. Additionally, beam couplings are comparatively cheaper than other types of rotary joints, and they require minimal maintenance.

The materials of a beam coupling should be considered early in the specification process. They are typically made of aluminum or stainless steel, but they can also be manufactured from Delrin, titanium, and other engineering grade materials. Beam couplings are often available in multiple sizes to fit specific shaft diameters.

Beam couplings are a key component of motion control systems. They provide excellent characteristics when used properly, and they are a popular choice for many applications. A thorough understanding of each type of coupling will help to prevent coupling failure and enhance system performance. Therefore, it is important to choose the right coupling for your application.

Various types of beam couplings have unique advantages and disadvantages. The FCR/FSR design has two sets of three beams. It is available in both metric and inch shaft sizes. The FCR/FSR couplings are ideal for light-duty power transmission applications. A metric shaft is more suitable for these applications, while an inch shaft is preferred for heavier duty applications.

Two types of beam couplings are available from Ruland. The Ruland Flexible beam coupling has a multi-helical cut design that offers a greater flexibility than commodity beam couplings. This design allows for higher torque capabilities while minimizing wind-up. In addition, it is also more durable than its commodity counterparts.

Flexible coupling

A flexible coupling is a versatile mechanical connection that allows for the easy coupling of two moving parts. The design of these couplings allows for a variety of stiffness levels and can address a variety of problems, such as torsional vibrations or critical speed. However, there are a number of tradeoffs associated with flexible couplings.

One of the biggest issues is the installation of the coupling, which requires stretching. This problem can be exacerbated by cold temperatures. In such a case, it is vital to install the coupling properly. Using a gear clamp is one of the most important steps in a successful installation. A gear clamp will keep the coupling in place and prevent it from leaking.

Another common type of flexible coupling is the gear coupling. These couplings are composed of two hubs with crowned external gear teeth that mesh with two internally splined flanged sleeves. The massive size of the teeth makes them resemble gears. Gear couplings offer good torque characteristics but require periodic lubrication. These couplings can also be expensive and have a limited number of applications.

Another type of flexible coupling is the SDP/SI helical coupling. These couplings can accommodate axial motion, angular misalignment, and parallel offset. This design incorporates a spiral pattern that makes them flexible. These couplings are available in stainless steel and aluminum.

A flexible coupling has a wide range of applications. Generally, it is used to connect two rotating pieces of equipment. Depending on its design, it can be used to join two pieces of machinery that move in different directions. This type of coupling is a type of elastomeric coupling, which has elastic properties.

There are many types of flexible couplings available for different types of applications. The purpose of a flexible coupling is to transmit rotational power from one shaft to another. It is also useful for transmitting torque. However, it is important to note that not all flexible couplings are created equally. Make sure to use a reputable brand for your coupling needs. It will ensure a reliable connection.

The simplest and most commonly used type of flexible coupling is the grid coupling. This type of coupling uses two hubs with slotted surfaces. The steel grid is allowed to slide along these slots, which gives it the ability to flex. The only limitation of this type of coupling is that it can only tolerate a 1/3 degree misalignment. It can transmit torques up to 3,656 Nm.

Magnetic coupling

Magnetic coupling is a technique used to transfer torque from one shaft to another using a magnetic field. It is the most common type of coupling used in machinery. It is highly effective when transferring torque from a rotating motor to a rotating shaft. Magnetic couplings can handle high torques and high speeds.

Magnetic coupling is described by the energy difference between a high-spin state and a broken symmetry state, with the former being the energy of a true singlet state. In single-determinant theories, this energy difference is called the Kij. Usually, the broken-symmetry state is a state with two interacting local high-spin centers.

The magnetic coupling device is regarded as a qualitative leap in the reaction still industry. It has solved a number of problems that had plagued the industry, including flammability, explosiveness, and leakage. Magnetic couplings are a great solution for many applications. The chemical and pharmaceutical industries use them for various processes, including reaction stills.

Magnetic couplings are a good choice for harsh environments and for tight spaces. Their enclosed design keeps them fluid and dust-proof. They are also corrosion-resistant. In addition, magnetic couplings are more affordable than mechanical couplings, especially in areas where access is restricted. They are also popular for testing and temporary installations.

Another use for magnetic coupling is in touch screens. While touch screens use capacitive and resistive elements, magnetic coupling has found a cool new application in wireless charging. While the finger tracking on touch screens may seem like a boley job, the process is very sensitive. The devices that use wireless charging need to have very large coils that are locked into resonant magnetic coupling.

Magnetic couplings also help reduce hydraulic horsepower. They cushion starts and reduce alignment problems. They can also improve flow in oversized pumps. A magnetic coupling with an 8 percent air gap can reduce hydraulic HP by approximately 27 percent. In addition, they can be used in aggressive environments. They also help reduce repair costs.

Magnetic couplings are a great choice for pumps and propeller systems because they have the added advantage of being watertight and preventing shaft failure. These systems also have the benefit of not requiring rotating seals.

Shaft coupling

A shaft coupling joins two shafts and transmits rotational motion. Generally, shaft couplings allow for some degree of misalignment, but there are also torque limiters. Selecting the right coupling can save you time and money and prevent equipment downtime. Here are the main features to consider when purchasing a coupling for your application.

Shaft couplings should be easy to install and disassemble, transmit full power to the mated shaft, and reduce shock loads. A shaft coupling that does not have projecting parts should be used for machines that move or rotate at high speeds. Some types of shaft couplings are flexible while others are rigid.

Shaft couplings can be used in a variety of applications, including piping systems. They can be used to connect shafts that are misaligned and help maintain alignment. They can also be used for vibration dampening. Shaft couplings also allow shafts to be disconnected when necessary.

Shaft couplings can accommodate a certain amount of backlash, but this backlash must be well within the tolerance set by the system. Extremely high backlash can break the coupling and cause excessive wear and stress. In addition, excessive backlash can lead to erratic alignment readings. To avoid these issues, operators must reduce backlash to less than 2deg.

Shaft couplings are often referred to by different names. Some are referred to as “sliced” couplings while others are known as “slit” couplings. Both types offer high torque and torsional stiffness. These couplings are typically made from metals with various alloys, such as acetal, stainless steel, or titanium.

CZPT Pulley produces shaft couplings for a variety of applications. These products are used in high-power transmission systems. They have several advantages over friction couplings. In addition to minimizing wear, they don’t require lubrication. They are also capable of transmitting high torque and high speeds.

Another type of shaft coupling is the universal coupling. It is used to transmit power to multiple machines with different spindles. Its keyed receiving side and flanges allow it to transmit power from one machine to another.

editor by czh 2023-01-13

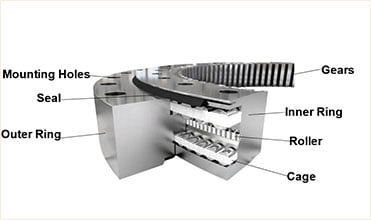

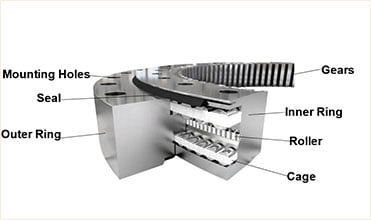

China manufacturer & factory supplier for china in Yaroslavl Russian Federation supplier High precision industry machinery Slewing Bearing 01-2202-00 slewing ring bearing With high quality best price & service

The continued enlargement of our ball bearings, mounted units and energy transmission solution lines, together with our focus to depth and good quality, has permitted EPG to gain broad acceptance to a various buyer foundation.PersonnelOur product sales people are properly skilled to accommodate your requests and converse English for your usefulness.

Overview

Swift Details

- Applicable Industries:

-

Building Material Outlets, Producing Plant, Farms

- Brand Title:

-

OEM

- Manufacturer:

-

syf

- Bore measurement:

-

two hundred-1300 mm

- Outdoors Diameter:

-

three hundred-8000mm

- Substance:

-

50Mn/42CrMo/Tailored

- Module:

-

eight

- Teeth:

-

syf

- Dimension:

-

2091*2342*70 mm

- Excess weight:

-

373 KG

Offer Capacity

- Supply Capability:

- 1500 Established/Sets for every Thirty day period

Packaging & Shipping and delivery

- Packaging Details

- 1. Bearing surface is coated with the anti-rust oil initial And then wrapped with the plastic movie

2. And then packed with Kraft paper and skilled belts

3. At very last, with wooden box totally at the outer packing to in void the rust or the moist

4. Packaging can be carried out in accordance to customer’s needs.”>HGB Packaging Particulars:

1. Bearing surface area is protected with the anti-rust oil first And then wrapped with the plastic movie

two. And then packed with Kraft paper and expert belts

3. At last, with picket box totally at the outer packing to in void the rust or the moist

four. Packaging can be accomplished in accordance to customer’s demands.

- Port

- China any Port

-

Lead Time

: -

Amount(Luggage) 1 – a hundred >100 Est. Time(times) 7 To be negotiated

Online Customization

If the equipment reducer experienced to be painted, the detents need to be covered to stop them from drying and getting rid of their seal. The machine perform of the fittings set up in the output shafts need an ISO H7 or h6 margin for the hollow shaft.

Why Pick Us

Product Description

one,One row four stage contact ball slewing bearing

2,Solitary row cross roller slewing bearing

3,Double-row ball slewing bearing

4,3-row roller slewing bearing

five,Roller/Ball Blend Slewing bearing.

Solitary row 4 point

contact ball slewing bearing

Solitary row cross

roller slewing bearing

Double Row

Ball slewing bearing

3 row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Type |

One row 4 stage speak to ball slewing bearing |

|

Rollng elements Upkeep Servicing on these models is straight ahead and like all moving elements these need their honest share of grease and must be greased routinely as these components work very hard and are topic to all that mother nature can offer for use and tear. Great grease is important right here put grease in right up until you see the old grease oozing out. Go easy on the “U” joints so you do not blow the seals. Limited bursts of a reduced pressured air grease gun or even greater a hand pump gun will do the work and need to be carried out based on hourly use. At least once a period the major and secondary shafts must be divided. All debris and any rust should be cleaned off. Take a look at completely for any symptoms of tension and utilize a liberal volume of grease. In addition to this, equally the PTO yoke holes need grease inside of of them at the very least after a calendar year alongside with the yoke lock pin. |

Steel ball / Cylinder Roller |

|

Rollng factors Substance |

GCr5/GCr15SiMn/Customized |

|

Bearing Content |

50Mn/42CrMo/42CrMo4V /Custom-made |

|

Cage Materials |

Nylon/ metal /copper |

|

Composition |

taper pin , Mounting holes,Interior ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore size |

fifty-10000mm |

|

Mounting hole |

By way of gap/Tapped hole |

|

Raceway hardness |

55-62HRC |

|

Internal and outer ring modulation hardness |

229-269HB/Customized |

|

Gear variety |

No gear ,Inside equipment , Exterior equipment. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certificate |

Ab muscles.BV,DNV,ISO9001,GL |

|

Application area |

Ladle turret,Stacker crane,Bucket wheel device,Solar heliostat Monitoring System,port crane, Cabling device,tower crane , offshore system,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing device,Wind blade transporter,defend tunneling equipment,tube drive bench,excavator |

|

Brand name Identify |

HGB |

|

Location of Origin |

HangZhou Henan |

|

Warranty |

twelve months |

|

Payment phrase |

T/T is our initial choice |

|

Packing specifics |

1,Filling with anti-rust oil 2.Corved with Plastic paper three.Corved with kraft paper four.Corved with Blue tie five.Set in wooden box |

Solution Information

|

Excavator Slewing Bearings are extensively employed for all manufacturers of excavators, go well with for follows types |

|||

|

Slewing Bearings For Hita chi |

EX40-1 EX60-1-2-3-5 EX70-5 EX90 EX100-1-2-3-5 EX110-5 EX120-1-2-3-5 EX130-5 EX200-1-2-3-5 EX210-5 EX220-5 EX270 EX300-1-2-3-5 EX-330 EX330-3 EX350-5 EX400-3 EX400-5 EX470-3 EX870 ZAX60 ZX55-R ZAX70 ZAX80 ZAX110 ZAX120 ZAX130 ZAX200-3-6 ZAX210 ZAX220-5 ZAX230 ZAX240 ZAX240-3 ZAX250-3 ZAX270-3 ZAX450-1 ZAX450-3 ZAX450-5 ZAX750 UH063 UH07-7 UH083 |

||

|

Slewing Bearings For E |

E45 E60 E70B E80 E110 E120B E305 E311 E312B/C E307B/C/D E308 E315 E200 E200B E320 E320B E320C E320D E320L E324D E325/B/C/D E330/B/C E345/B E350 E365 E380 E385 |

||

|

Slewing Bearings For Personal computer |

PC30 PC30-2 PC35 PC40 PC45 PC50 PC50-7 PC55 PC60-5-6-7 PC70 PC75 PC78 PC100-3-5 PC120-3-5-6-6E PC128 PC130-7 PC150-5-7 PC160-7 PC200-1-2-3-4-5-6-7-8 PC210-7 PC220-3-5-6 PC240-8 PC227 PC228 PC270-7 PC300-1-2-3-4-5-6-7 PC350-6-7 PC360-6-7 PC400-3-5-6-7-8 PC450-5-6 PC460-7 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 |

||

|

Slewing Bearings For Sumitomo |

SH50 SH60-1 SH120-1-2/A1/A2/A3/Z3/C3 SH120C3 SH260 SH200 A1/A2/A3/C2/C3/Z3 SH210-5 SH210-A5 SH220-3 SH225 SH240-3-5 SH280 SH350 |

||

|

Slewing Bearings For Hyundai |

R55-5-7 R60-5-7 R70-7 R80-7 R110-7 R130-5-7 R130LC-3-5 R150-7 R170-5 R200-3-5-7 R205-7 R210 R215-7 R220-5-7-9 R225LC-7 R260-7 R280 R290-7 R290LC-3 R290LC-7 R300LC R305LC-7 R320 R330LC R335-7 R375 R360LC-7 R450-7 R450LC R962 |

||

|

Slewing Bearings For Kato |

DH35 DH55 DH60 DH80-7 DH150-5-7 DH200 DH215-7 DH220-2-3-5-7-9 DH258-7 DH280-5 DX60 DX200 DX225 DX260 DX300 DH280 DH290-5 DH300LC-7 DH340 |

||

|

Slewing Bearings For Kobelco |

SK60-3-5 SK100 SK120-1-2-3-5 SK130-8 SK140-8 SK200-6 SK210-6 SK200-6E SK07 SK200-3-5-8 SK210-8 SK220 SK230-6 SK235 SK250-6-8 SK260-8 SK330-6 SK350-8 SK480-eight |

||

|

Slewing Bearings For LIUGONG & For XCMG |

CLG906 CLG907 CLG908 CLG915 CLG915D CLG205C CLG225C CLG220LC CLG225 CLG200 CLG200-3 CLG920D CLG922D CLG925D CLG936LC CLG936D XE60 XE210 XE215 XE150A/B XE230 XE370 210-8 220-8 |

||

|

Slewing Bearings For SANY |

SY65 SY75 SY135 SY185 SY195 SY200 SY205 SY210 SY215-7-8-9 SY235 SY300 SY305 SY310 SY335 SY360 SY365 SY420 |

||

|

Slewing Bearings For Volov |

EC55 EC210 EC210B EC240 EC290 EC360 |

||

|

Slewing Bearings For Liebherr |

R914 R916 R924 R944 |

||

|

Slewing Bearings For Yuchai |

YC15 YC20 YC35 YC60 YC6-5T YC85 YC210-8 YC230-8 YC350 YC400-8 |

||

|

Slewing Bearings For XGMA and For LONKIN |

XG60 XG808 XG815 XG820 XG822 XG823 XG825 LG6060 LG6075 LG6085 LG6090 LG6210 LG6230 LG6225 LG6235 |

||

|

Slewing Bearings For Atlas and For Sunward |

for Atlas3306LC 2006 TC360 2306 SWE50 SWE60 SWE70 SWE80 SWE90 SWE150 |

||

|

More Types for |

For LovolFR85 FR150 FR210 For Bobcat80 For SW210 SW230 For Takeuchi135 a hundred seventy five For Case CX210B For JCM906D JCM921 JCM922 For EPG75 161 For ZY80 ZY210 For JCB8056 JCB220 For ZW60 ZE80 JV60 SC360 HL60 |

||

Bearing Areas

Steel ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Substance

Cage: consist of integral cage, section cage and spacer-variety cage. twenty# steel or copper for integral and section cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, handful of felted wool.

Solitary row cross roller slewing bearing

Composed of two or a few rings. compact composition, gentle fat, substantial producing precision, little assembly gap and substantial requirement for set up accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial pressure, overturning minute and huge radial force at the exact same time,and extensively used in lifting transportation, building machinery and armed forces merchandise.

3 row roller slewing bearing

3 row roller bearing able to bear all varieties of masses at the identical time, it is the greatest a single of the four structural items with huge axle and radial proportions and agency structure. Particularly suitable for large equipment demanding larger diameter, this kind of as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,massive tonnage truck crane,heavy machinery and so on.

Single row four level contact ball slewing bearing

Solitary row four point composed of two seat rings. has compact construction, light fat, and 4-point get in touch with among metal ball and arc raceway. It caEPG is inclined to cooperate sincerely and build commonly with pals!n bear axial power, radial power and overturning instant at the same time. The building equipment of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be picked.

Much more Merchandise

More Goods

A lot more Items

A lot more Items

About Us

Vast production workshop and robust production team as a assistance,guarantee the goods can be developed by necessary quality and amount. andThereby enhance the consumer rewards.

The over is our production tools with innovative technological innovation , the secure and longevity bearing create from these tools .

We focus in the creation of producing slewing ring bearings or turntable Bearings.The Independent R&D and revenue team in HGB , also do our ideal for particular needsWe supply higher-precision and higher-high quality slewing bearings, which are widly employed in many fields,these kinds of as hoisting and conveying equipment, design engineering equipment, harbour equipment, wind electricity technology, radar and missile launchers and so on.

Certificate

FAQ

one.Q: Are you trading organization or producer ?

A: We are specialist slewing bearing manufacturer with twenty years’ experience.

2.Q: How lengthy is your shipping and delivery time?

A: Typically it is 4-5 times if the products are in inventory. or it is 45 days if the items are not in

inventory, Also it is according to quantity.

3.Q: Do you offer samples ? is it cost-free or additional ?

A: Indeed, we could supply the sample, it is added.

four.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in progress, harmony before shipment.

5.Q: Can you provide unique customization in accordance to the operating problems?

A: Sure, we can layout and make the slewing bearings for distinct operating circumstances.

six.Q: How about your promise?

A: We provide lifelong after-sales complex provider.

Speak to Us

Wechat/Whatsapp: +86 13083988828

Skype: +86 13083988828

Firm Identify: HangZhou EPG – 1 of the bigggest transmission manufacturer in China – At any time-Power Transmission Bearing Technology Co., Ltd

Place of work Tackle: Space B8F, Block B, shenhua highway 789 – jianqiaogongshe Intercontinental, XiHu District, HangZhou Metropolis,China

Cellphone: +86 13083988828

Factory Handle: Bearing zone in XiHu County, HangZhou Town, China

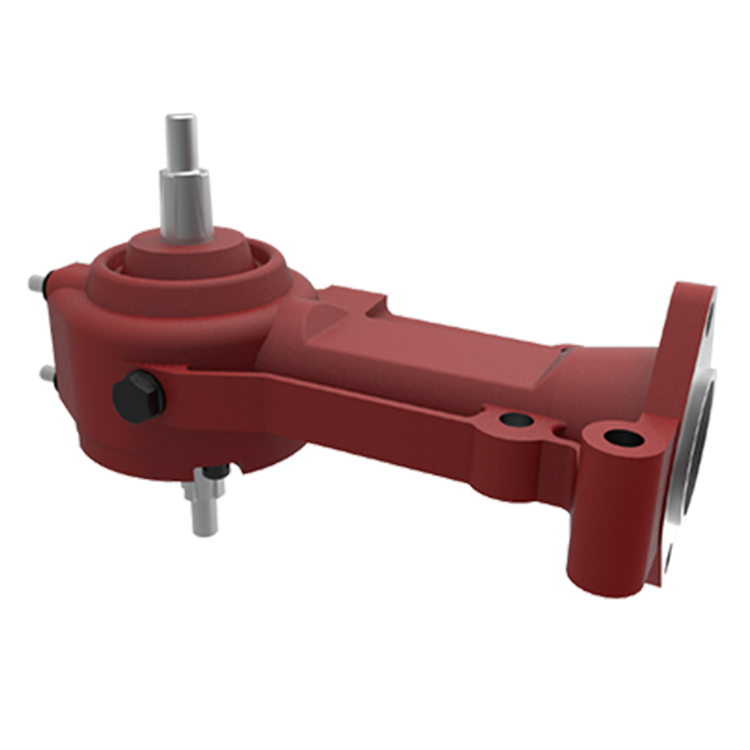

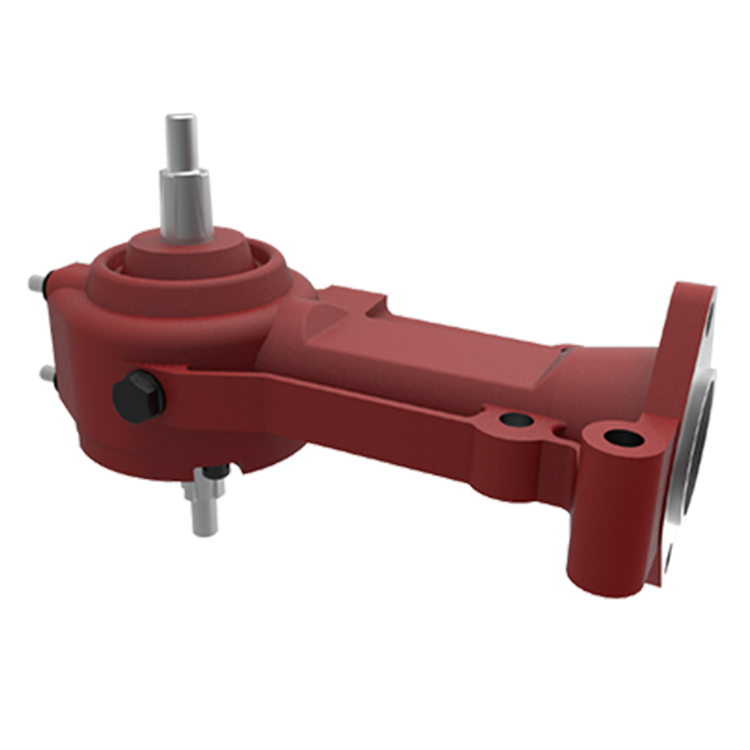

Best China manufacturer & factory Top in Zaporizhzhya Ukraine Quality Agricultural Machinery Pto Drive Shaft With Overrun Clutch With high quality best price

Superior thermo remedy products, this sort of as community heat therapy oven, multi-use thermo treatment oven, and many others.

Overview

Swift Information

- Warranty:

-

1.5 a long time

- Relevant Industries:

-

Producing Plant

- After Warranty Services:

-

On the web support

- Neighborhood Service Location:

-

None

- Showroom Place:

-

Italy

- Sort:

-

Shafts

- Place of Origin:Zhejiang, China

- Model Name:

-

OEM

- Local Support Place:

-

Italy

- certificate:

-

CE

- Content:

-

Metallic

- Shade:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Style:

-

Customized

- Purposes Worm gearboxes are obtainable to go well with the prerequisite of a lot of apps. For foods provider and other washdown applications, worm gear bins are offered in tough, non-absorbent white or steel epoxy coatings. They are widely utilized in computer systems. The biggest gain that the worm gearbox delivers is the permanence of info composed to them. Application that accompanies a worm gearbox typically permits to create a virtual push based on the point out of the disk at a presented info in the earlier. They are also well-liked for backup. Worm cartridges store nicely and effortlessly for long periods of time. Certification:

-

CE Certificate

Offer Capability

- Offer Potential:

- 20000 Piece/Pieces for each Month

Packaging & Shipping

- Packaging Details

- Packing specifics:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

On the web Customization

Solution Details

Item Information

PTO Shaft

The energy just take-off (PTO)EPG main creation is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting equipment and equipment. is a refined system, making it possible for implements to attract energy from the engine and transmit it to yet another application. It functions as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electrical power just take-off shaft (PTO shaft) is a vital component, made and made for continuous large-duty use. A very good PTO shaft should be strong adequate to bear the torsion and shear anxiety and decrease vibration.

Setforge, the forging subsidiary of Ever-Electrical power Group, manufactures cold extruded PTO shafts for all varieties of agriculture vehicles. Our PTO shafts provide wonderful dependability and sturdiness during every day use.

EP Group has been internationallyA power take-off or power takeoff (PTO) is any of numerous techniques for having energy from a energy supply, such as a running engine, and transmitting it to an software these kinds of as an attached employ or separate device. recognized as a reliable worldwide provider. Our point out-of-the-art production procedure and skilled engineers guarantee the leading-top quality of all Farinia components.

| After Guarantee Provider | Movie specialized support |

| Relevant Industries | Manufacturing Plant |

| Neighborhood Provider Spot | Italy |

| Showroom Spot | Italy |

| Guarantee | 1.5 years |

| Sort | Shafts |

| Spot of Origin | China |

| China | Zhejiang |

| Model Identify | EPG |

| certification | CE |

| Content | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Style | Personalized |

| Certificate | CE Certification |

Item Show

Merchandise Display

6″ Rock Auger

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

At any time-Power Group

EPG have high-tech machinery and test gear. We can create entire world class high precision items.

Certifications

Certifications

Shipment & Payment

Our Benefits

A: Your inquiry relevant to our merchandise or rates will be replied in 24 hrs.

B: Defense of your revenue spot, tips of layout and all your personal details.

C: Best quality and aggressive price.

……

faq

FAQ

1) How can I place buy?

A: You can speak to us by e-mail about your get details, or spot order on line.

2) How can I pay out you?

A: Following you verify our PI, we will request you to pay. T/T (HSBC financial institution) and Paypal, Western Union are the most usual techniques we are using.

……

Best China manufacturer & factory Professional in Kaduna Nigeria Factory Made Practical Agricultural Machinery Cross Kits With high quality best price

assures the stability and consistency of the important perform of components.

Overview

Swift Details

- Guarantee:

-

1.5 years

- Applicable Industries:

-

Production Plant

- Following Guarantee Provider:

-

On the internet support

- Local Service Location:

-

none

- Showroom Location:

-

ITALY

- Location of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Local Provider Location:

-

Italy

- certificate:

-

CE

-

Materials:

These are compact, heavy-responsibility drives that provide prolonged-daily life performance functions and simplified routine maintenance. They include double and triple reduction units. They are available in a assortment of configurations for greatest positioning versatility. They supply very good toughness and toughness. The large energy output shaft assures ability for higher torque and overhung hundreds. -

Metallic

-

PTO shaft connectors on tractors are not standardized which can lead to difficulties when connecting the PTO shaft. For example, some older tractor models have the relationship flange nearer to the tractor alone producing it hard to connect and direct to a likely protection hazard.

- Processing of yoke:

-

Forging

- Style:

-

Customized

- Certification:

-

CE Certification.

Offer Potential

- Source Ability:

- 20000 Piece/Parts per Thirty day period

Packaging & Shipping

Our firm has solid financial energy, builds up a technician staff contingent with high quality, possesses the production assembly line of technicalization in China and ideal system examining on solution high quality and runs marketing networks throughout the country.

- Packaging Information

- Iron crates

- Port

- NINGBO OR SHANGHAI

On the web Customization

Item Details

Solution Information

PTO Shaft

The power get-off (PTO) is a sophisticated system, making it possible for implements to attract strength from the motor and transmit it to another application. It performs as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power consider-off shaft (PTO shaft) is a vital part, developed and produced for ongoing weighty-obligation use. A great PTO shaft must be robust enough to bear the torsion and shear pressure and reduce vibration.

Setforge, the forging subsidiary of Ever-Electrical power Team, manufactures chilly extruded PTO shafts for all types of agriculture autos. Our PTO shafts supply excellent dependability and sturdiness in the course of everyday use.

EP Group has been internationally identified as a dependable world-wide provider. Our state-of-the-art production approach and knowledgeable engineers make certain the best-quality of all Farinia components.

| After Warranty Provider | Online video technological assist |

| Relevant Industries | Production Plant |

| Regional Services Spot | Italy |

| Showroom Place | Italy |

| Guarantee | 1.5 years |

| Area of Origin | China |

| China | Zhejiang |

| Manufacturer Identify | EPG |

| certificate | CE |

| Materials | Metallic |

| Processing of yoke | Forging |

| Design | Custom-made |

| Certification | CE Certification. |

Item Screen

Item Show

CAT 23 Quick Hitch

PTO Push Line Gen …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Electrical power Team

EPG have substantial-tech machinery and examination products. We can make world course substantial precision products.

Certifications

Certifications

Cargo & Payment

Our Positive aspects

A: Your inquiry connected to our goods or rates will be replied in 24 hours.

B: Defense of your revenue location, concepts of layout and all your personal information.

C: Greatest high quality and competitive cost.

……

faq

FAQ

1) How can I area order?

A: You can speak to us by e-mail about your get particulars, or area order on line.

2) How can I spend you?

A: After you confirm our PI, we will request you to pay out. T/T (HSBC bank) and Paypal, Western Union are the most typical approaches we are using.

……

Roller made in China – replacement parts – roller chain escalator in Oklahoma City United States Plastic Conveyor Drag Chain Belt Conveyor CNC Machinery Part with ce certificate top quality low price

We – EPG Team the largest Chain and agricultural gearbox factory in China with 5 distinct branches. For far more specifics: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

Due to our sincerity in providing very best service to our clients, knowing of your wants and overriding feeling of responsibility towards filling buying needs,a specialised provider of a total variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….engineering With a lot of years’ encounter in these lines, we have been distinguished from other suppliers in China by our rewards in competitive pricing, on-time supply, prompt responses, on-hand engineering assistance and very good soon after-revenue solutions. class chains & precision roller chains. One strand chain, multi-strand chains, double pitch chains, corrosion resistant chains, self-lubricating chains, attachment chains, leaf chains, and specialty chains. roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also obtainable. Other electrical power transmission goods contain pillow blocks, conveyor idlers, conveyor pulleys, drive shafts, equipment racks, equipment reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, speed reducers, sprockets, tapered bushings, tensioners, torque limiters, and common joints. Companies such as bearing reconditioning and restore, ball screw fix, personalized deal machining, gearbox restore and overrunning clutch restore services are obtainable. Roller chains can be used in conveyor and machinery producing, industrial processing, equipment rebuilding, squander drinking water, sand and gravel, instrument and die, steel, metals and scrap processing industrial applications. ZheJiang EPT EPT Technology Co., Ltd.

Our ISO,CE,BV, SGS Accredited, cable drag chains/ EPT Chains/Transmission Chains/Defense cable chains

Exclusive Attributes:

1,Uncooked substance control, such as various kinds of test, this kind of us DSC, flow price, humidity content test, tensile te EPT and so on.

2,Uncooked content handle, such as different varieties of take a look at, these kinds of us DSC, movement charge, humidity content material examination, tensile te EPT etc.

3,We seek feedbacks from all our end users, and keep bettering our good quality, and correct any framework deficiency.

four,A lot of moulds for numerous sizes to choose. Also variation types, versions. We can make new mould for specific requirements.

five,Ideal for substantial-speed reciprocating motion of the mechanical products ,for wire,cable,tubing,the trachea and conduit traction and safety.

| Rapid Particulars | |

| Model Identify: | AOPRO |

| Substance: | Refinforced Nylon |

| Applicable Industries: | EPT Plant, EPT Mend Stores, Printing Retailers, Strength & Mining, EPT tools |

| Problem: | New |

| Soon after Warranty Services: | Video technical support, On the internet assistance |

| Guarantee: | twelve months |

| Purpose: | Cable defense |

| Shade: | Black with yellow or colored pin |

| Temperature Assortment: | -40°C~130°C |

| Certificate: | ISO9001,CE,SGS |

| Characteristic: | Anti-corrosion |

| Structure: | open up type |

| Functioning pace: | 2-5 m/s |

Much more Descriptions:

Hot income items:

Organization or goods Certifications:

ZheJiang EPT EPT Technologies Co., Ltd. is a specialist design and style, production and sales of numerous engineering drag chains, shut and semi-shut plastic chains, bridge chains, silent chains, bolstered chains, conveyor chain plates and various machine device equipment, Extensive enterprise of operating elements.

Because its establishment, the business has always adhered to the enterprise support principle of “technological innovation, excellent high quality, timely service, dedicated and grateful”, constantly absorbing new suggestions in design, greedy new trends, has utilized for a variety of patents, and strictly managed the creation process.

Quality management, complete comply with-up provider on following-product sales, insi EPT on making substantial-quality goods, permit customers get pleasure from the merchandise support program of “excellent top quality and very good price, no problems throughout the approach”!

Our solution is broadly employed in various equipment equipment, these kinds of as: Numerous manipulators, woodworking machinery, food equipment, printing equipment, ceramic equipment, glass machinery, a variety of CNC machining centers, engraving devices, and many others., our company’s personal design and style department, mould manufacturing unit, Injection molding plant, assembly plant, a variety of non-stHangZhourd drag chains, unique chains, device tool components, etc.

Can be customized processing The company can also undertake numerous kinds of automatic creation lines, versatile creation lines, linear conveyor belts, screw conveyor towers, etc. Design, processing and set up organization!

Q:Is your company a manufacturing facility or a trading company?

A:We are a specialist manufacturer over 6 years, so you will appreciate the be EPT price tag and competitive price.

Q: Do you offer samples ? is it free of charge or further ?

A: Of course, we could offer the sample for free of charge charge but do not spend the co EPT of freight.

Q: What is the high quality assurance you supply? How do you control quality?

A: established methods for checking goods at all phases of the manufacturing procedure – raw supplies, operate in progress materials, verified or tested supplies, completed merchandise, and so on.

Q:Can you be a OEM brand name?

A:Of course, we can. OEM / ODM accessible.

Q: How extended is your supply time?

A: Normally it is 5-10 days if the merchandise are in inventory. or it is 15-twenty days if the merchandise are not in stock, it is in accordance to quantity.

Q:What are your conditions of payment?

A:Typically we acknowledge telegraphic transfer, we can also accept LC, paypal and Western Union remittance, and so on.

Q:Can we use our possess transportation agent?

A:Indeed, you can. We can also advise some dependable forwarders for your reference.

The use of unique gear manufacturer’s (OEM) portion figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating item use and compatibility. Our business and the detailed alternative areas contained herein are not sponsored, approved, or manufactured by the OEM.

Best China manufacturer & factory engineering machinery attachment hydraulic earth auger SC40000 For 22T-36T Excavator With high quality best price

EPG was awarded with “famous product of Zhejiang Province” and “famous brand of Zhejiang Province”.

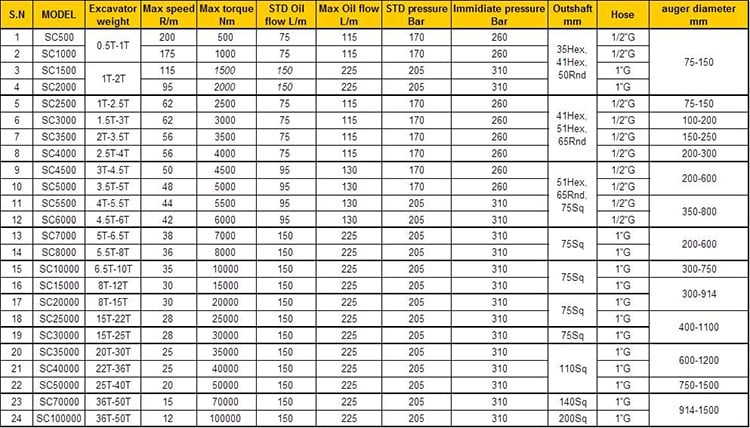

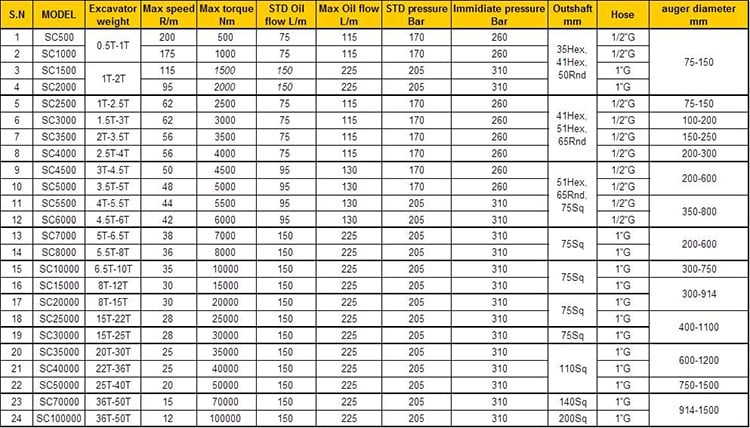

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

none, UniteOur factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China. d States

- Showroom Location:

-

United States

- Type:

-

Bearing

- Use:

-

Cultivators

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Application:

-

dig hole, tree planting, solar project

- condition:

-

new

- Suitable:

-

1-50 ton excavator,crane ,skid steer loader

- auger diameter:

-

A PTO shaft transfers the power from the tractor to the PTO powered attachment. This enables the tractor to power a variety of tractor implements including flail mowers, wood chippers, rotary tillers, excavators, and more.

75-1500mm

- Depth:

-

20M

- STD oil flow:

-

75L/M

- STD pressure:

-

170 bar

- outshaft:

-

41/51HEX, 65 Rnd,75Squ

- Color:

-

blue or black

Supply Ability

- Supply Ability:

- 1000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- BOX

- Port

- QINGDAO,DALIAN, SHANGHAI, NINGBO

-

Lead Time

: -

Quantity(Sets) 1 – 10000 >10000 Est. Time(days) 30 To be negotiated

Online Customization

engineering machinery attachment hydraulic earth auger EPG40000 For 22T-36T Excavator

Product Description

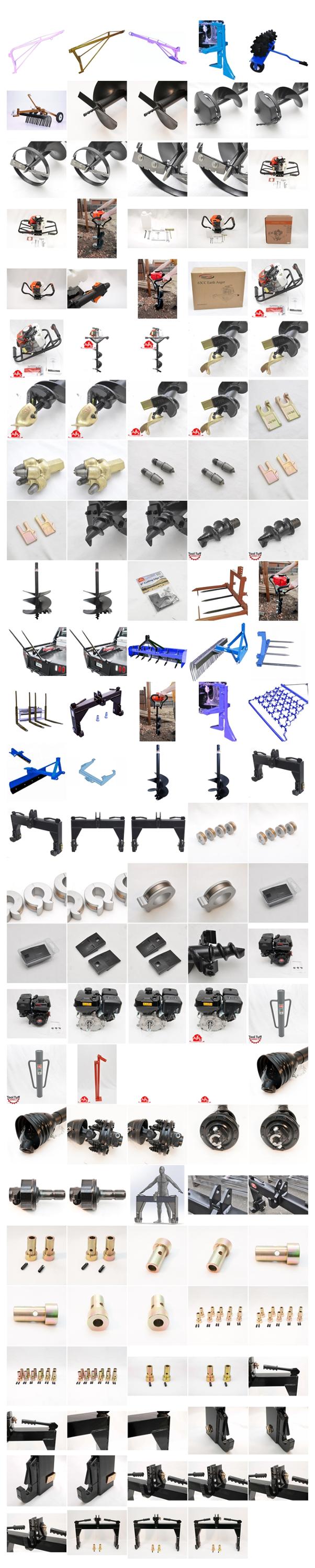

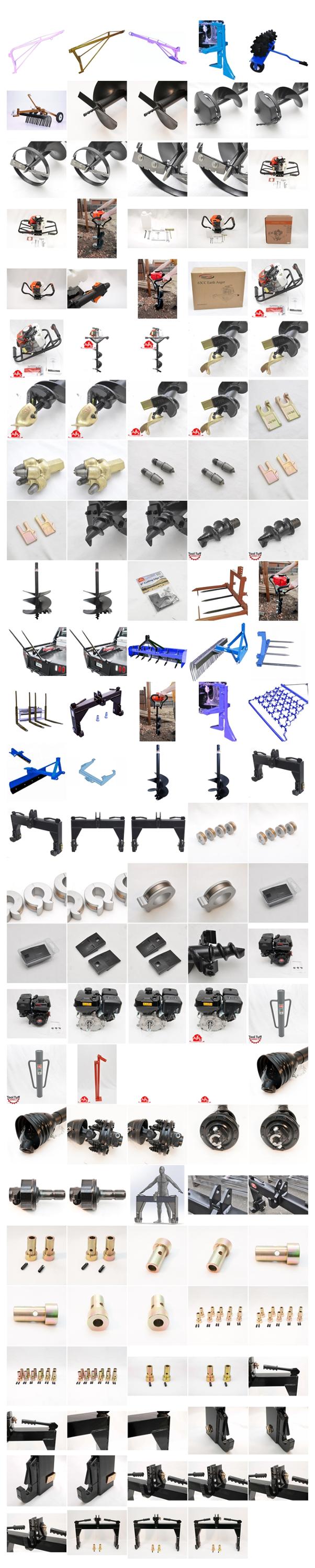

Earth Drills are renowned throughout the world for being the best augur system available. A large range of models are available to suit any machine and hole boring task from the smallest fencing job through to major piling works. With a revolutionary gearbox and non-dislodgement shaft, the EPG Earth Drill is built to out-perform and outlast, turning your machine into a truly universal piece of equipment.

Why we choose this earth auger?

It is obviously that earth auger is more efficient than manual work. Besides, using our product is safer than manual work. The hole which dig by the earth auger is more beautiful than man did.

Features & Benefits

– Non-dislodgment shaft.

– Epicyclic Gearbox

– Hose & Coupler options

– High quality hydraulic motor

– Forged hood ears

– Shock-lock tooth locking system

– Augers from 75mm to 1200mm

– new earth drills

Specification

Auger Drive

1.Forged hoods ears: Deal with the heavy strain of daily use. Contact surface wider and safer.

2.American Motor: Developing the most reliable wear parts.

3.ERICYLIC gearbox: Unique planetary gearbox. Multiplied output torque. ExtremeYou benefit from our comprehensive knowledge of the interaction between all the components in the drive train. For precise sizing and design of the entire drive train, we use our innovative EPG ® 5 design software. efficiency.

4.NON-dislodgement shaft: Assembled top down locked into earth drill house. Never fall out. Provided a safer environment.

5.18 Month After-sales service for auger drive.

hole digger ground drill Ground Hole Digger Earth Drill Earth Auger Ground Hole Drill

How to choose the most suitable type?

Related spare parts

Our auger teeth have patented unique design.Different teeth for different earth condition.

With those, I believe it is no problem to dig your dream hole.

more auger photos

Factory & Packaging

FAQ

Q: HOW CAN I CHOOSE THE SUITABLE EARTH DRILL?

A:PLEASE REFER TO BELOW QUESTIONS:

- 1. Brand and model of Excavator/Backhoe/Skid Steer loader?

- 2. Diameter of hole to be drilled?

- 3. Depth of hole to be drilled?

- 4. Ground type to be drilled?

Once you have answered the above you can easily make the correct choice.

Q: DO I NEED TO PURCHASE SPARE PARTS WHEN ORDERING AN EARTH DRILL?

A: It is not necessary to purchase spare parts for the Planetary Drive as this is a sealed unit, however it is important to follow the service schedule as outlined in the operators manual. It is advisable to purchase spare wearing parts (teeth and Pilots).

Q: CAN THE EARTH DRILL FIT A VARIETY OF MACHINES?

A: Yes, as long as the carrier’s specifications agree with the parameters of the Earth Drill as outlined in our catalogue.

Q: HOW DO I FIT THE EARTH DRILL TO MY MACHINE?

A: There are four types of mounting linkage available;

- Double Pin Hitch: to be used with excavators fitted with quick couplers.

- Double Pin Cradle hitch: also to be used with excavators fitted with quick hitch, in addition the Cradle hitch can be used to stabilise the Earth Drill whilst travelling around the site and also to aid in the clearing of spoil from the auger.

Q: WHAT CAN I DRILL?

A: There are 3 types of cutting teeth available,

1.Earth and Clay Teeth: Suitable for drilling earth and clay.

2.Tungsten Teeth: Suitable for drilling hard and abrasive ground.

3.Rock Teeth: Suitable for drilling soft, fractured, rock.

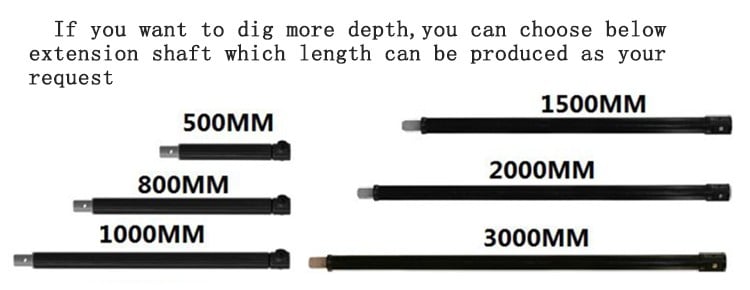

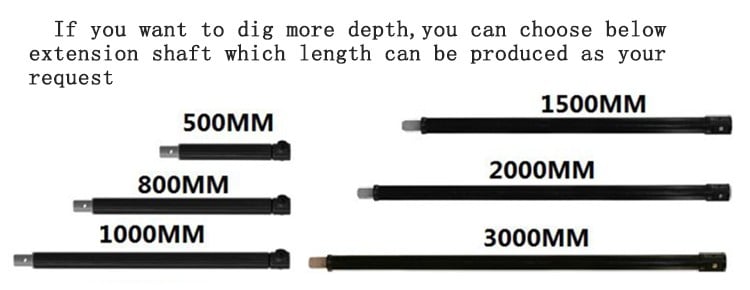

Q: HOW DEEP CAN I DRILL?

A: There are extensions available for every Earth Drill however maximum drilling depth depend on the following conditions;

- Diameter of hole to be drilled

- Depth of hole to be drilled

- Type of parent machine to be used

- Ground type to be drilled

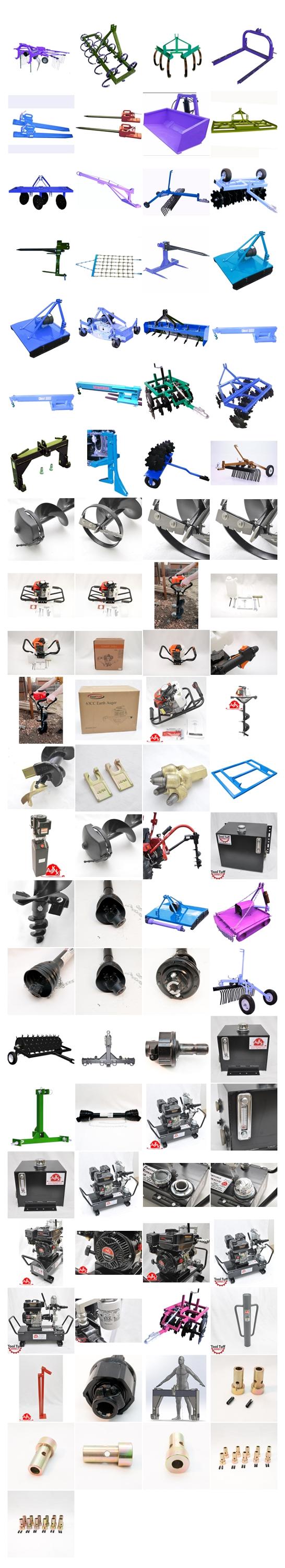

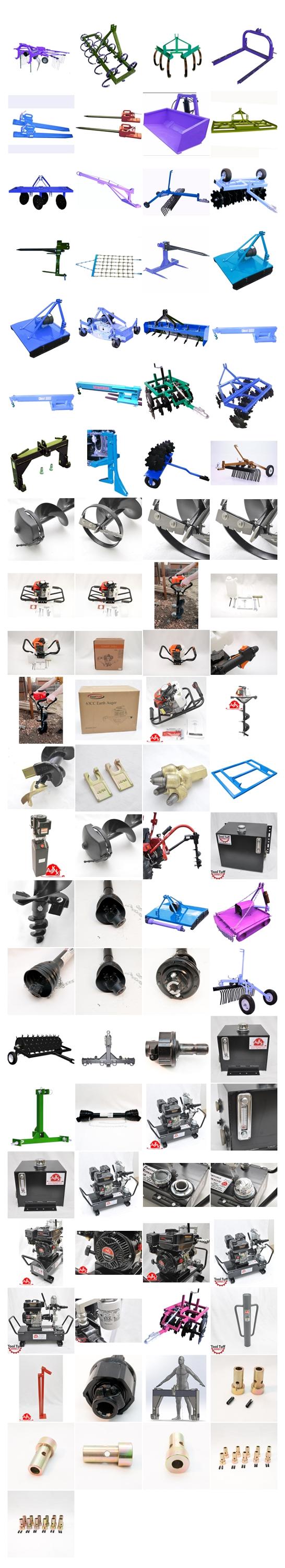

Other attachments

China best quality low sales price for china manufacturer CNC machine turning agricultural machinery and equipment parts Cotton Picker spindle Factory Manufacturer and Supplier -from Pto-shaft.com

Major merchandise consist of: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, mix rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough idea and share, cultivator tine, casting elements and so on.

Overview

Swift Details

- Warranty:

-

1.five a long time

- Relevant Industries:

-

farms

- Right after Guarantee Services:

-

Video clip specialized help

- Neighborhood Provider Place:

-

canada. turkey. None

- Showroom Area:

-

Egypt

- Online video outgoing-inspection:

-

Offered

- EPT Te EPT Report:

-

Presented

- Marketing and advertising Sort:

-

EPT Merchandise 2020

- Warranty of core factors:

-

1.5 several years